Ozone Library

Ozone Fact Sheet

This fact sheet provides information about ozone, including its production, properties, benefits, and safe use. Ozone is a molecule made up of three oxygen atoms, and it is naturally formed by reactions involving ultraviolet rays or by the electrical discharge of lightning. The fact sheet includes a chart comparing the oxidation potential of ozone to other oxidizers, explaining that ozone has no toxic byproducts or potential health hazards when appropriately used as a microbicide. The fact sheet also provides information on the half-life of ozone in water and the methods for producing ozone, such as corona discharge and plasma block. Additionally, it discusses the factors affecting mass transfer in ozone-contacting systems. This fact sheet is informative and valuable for anyone interested in understanding ozone and its properties.

OZONE HALF-LIFE

The half-life of ozone refers to the amount of time required for half of a given quantity of ozone to decay into oxygen. Ozone is an unstable gas that readily decomposes into molecular oxygen. Therefore, the half-life of ozone is an important factor to consider when determining its effectiveness in various applications.

Typical Dissolved in Water Ozone Half-life (PH=7) time as a Function of Temperature

| Half-life time | Temp |

|---|---|

| ∼ 30 minutes | 15 ºC |

| ∼ 20 minutes | 20 ºC |

| ∼ 15 minutes | 25 ºC |

| ∼ 12 minutes | 30 ºC |

| ∼ 8 minutes | 35 º |

Typical Gaseous Ozone Half-life time as a Function of Temperature

| Half-life time | Temp |

|---|---|

| ∼ 3 months | -50 ºC |

| ∼ 18 days | -35 ºC |

| ∼ 8 days | -25 ºC |

| ∼ 3 days | 20 ºC |

| ∼ 1.5 hours days | 120 ºC |

| ∼ 1.5 seconds | 250 ºC |

Click here to read about how to Compensate for the Half-Life of Ozone in Water

OZONE CONCENTRATION AND CHEMISTRY

Ozone concentration is a critical factor in determining its effectiveness in various applications. The concentration of ozone can vary depending on factors such as the method of generation, temperature, and humidity. For instance, ozone generated through corona discharge typically has a higher concentration compared to other methods.

Ozone is a powerful oxidizer that can react with a wide range of organic compounds, including bacteria, viruses, and other microorganisms. The chemistry of ozone is complex and involves various chemical reactions. In direct reactions, ozone reacts directly with organic compounds to form aldehydes, ketones, carboxylic acids, and peroxides. These reactions are crucial in applications like water treatment and air purification, where ozone’s ability to break down harmful substances is utilized.

In indirect reactions, ozone reacts with water to form hydroxyl radicals. These radicals are highly reactive and can oxidize organic compounds even more effectively than ozone itself. This advanced oxidation process is particularly useful in degrading persistent organic pollutants. Understanding these chemical reactions and the factors affecting ozone concentration, such as temperature and humidity, is essential for optimizing its use in different applications.

The goal is to introduce enough ozone into the water to compensate for the ozone half-life, ensuring a consistent residual ozone concentration.

For example, suppose we’re using ozone in an aquaculture system and want to maintain a concentration of 0.4 mg/L of ozone in a 30,000-liter (30 m^3) shrimp pond. The indirect reaction of ozone with water can affect the residual ozone concentration, as it produces highly reactive hydroxyl radicals that oxidize various substances.

1. Calculate the initial amount of ozone required:

Required ozone quantity (NC) = Desired concentration x Pond volume

NC = 0.4 mg/L x 30,000 L = 12,000 mg

Convert from milligrams to grams by dividing by 1,000:

Required ozone quantity (NC) = 12,000 mg / 1,000 = 12 g

So, we would need 12 grams of ozone to maintain the desired concentration in the shrimp pond.

2. Take into account that ozone degrades over time.

Let’s assume a water temperature of 25ºC, the half-life of ozone in the pond water is 0.25 hours (∼ 15 minutes at 25ºC).

To determine the amount of ozone to inject per hour for compensation, use the following formula:

Ozone quantity (NC) / Half-life (HL) = Ozone quantity (C)

Where:

– Ozone quantity (NC): The amount of ozone required to maintain the desired concentration without compensating for the half-life. – Half-life (HL): The half-life of ozone based on water temperature and other conditions. – Ozone quantity (C): The amount of ozone that needs to be injected to maintain the residual concentration under current water conditions.

Assuming that water conditions remain constant and the half-life of ozone is 0.25 hours (∼ 15 minutes at 25ºC), the formula would be:

12 g / 0.25 h = 48 g

We would need to inject 48 grams of ozone per hour (four times more) to compensate for the degradation and maintain a concentration of 0.4 mg/L in the shrimp pond.

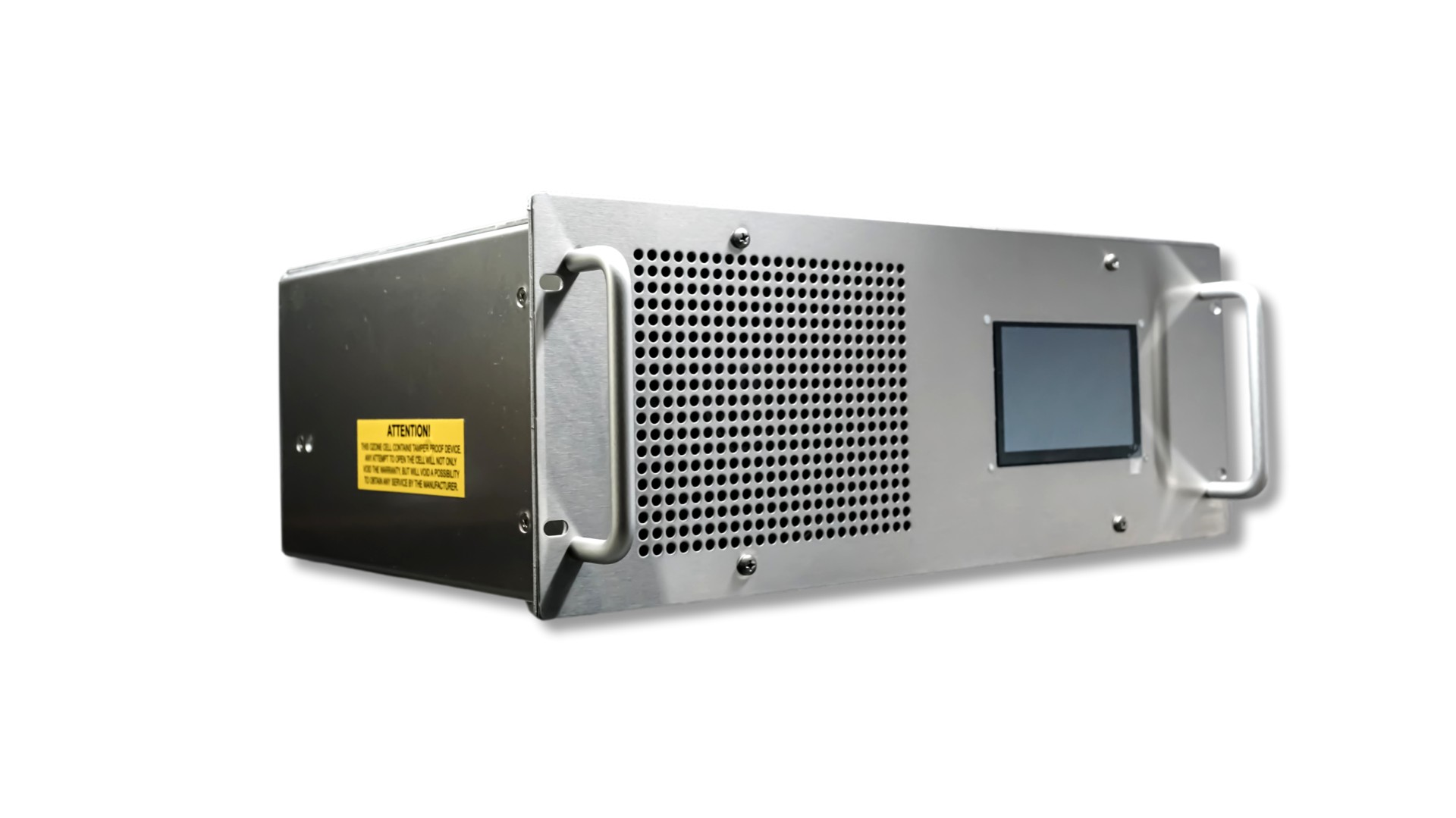

Please note that it’s essential to recognize that not all the ozone generated can be fully dissolved in the water. To achieve the 48 grams of ozone injection per hour, you may need to invest in a high-concentration ozone generator, such as the Atlas 60, capable of dissolving more than 80% of the produced ozone.

Ozone Decomposition

Ozone decomposition is a critical factor in determining its effectiveness in various applications. Ozone decomposes into oxygen and other compounds, including hydroxyl radicals, which are highly reactive and can oxidize organic compounds. The rate of ozone decomposition depends on various factors, including temperature, pH, and the presence of organic compounds.

Thermal decomposition occurs when ozone is exposed to high temperatures, causing it to break down rapidly into oxygen. Catalytic decomposition involves the use of catalysts to accelerate the breakdown of ozone, which is often used in industrial applications to control ozone levels. Radiolytic decomposition, on the other hand, involves the use of radiation to decompose ozone, which is less common but highly effective.

Understanding the mechanisms of ozone decomposition is essential for designing and operating ozone systems. For example, in water treatment, controlling the temperature and pH can optimize the decomposition rate, ensuring that ozone remains effective for the desired duration. Similarly, in air purification, managing the presence of organic compounds can help maintain the desired ozone concentration.

OZONE O3

Ozone (O3) is a molecule consisting of three oxygen atoms, with two oxygen atoms forming a stable oxygen molecule (O2) when ozone decomposes, and a molecular weight of 48.00 g/mol. It is a pale blue gas with a distinct pungent odour and is heavier than air, with a vapour density of 1.65 compared to air’s 1.0. Ozone is an unstable molecule that readily decomposes to form oxygen molecules (O2).

Ozone can also form hydroxyl radicals (HO) when it reacts with water, which are powerful oxidizing agents that can further degrade organic pollutants. This process is known as the advanced oxidation process (AOP). Ozone is a versatile and powerful oxidizing agent with many applications in water and wastewater treatment, air purification, and industrial processes.

- Molecule

- 1840: C. F. Schönbein

- Three oxygen atoms

- Properties

- Molecular weight: 48,00 g/mol

- Boiling point: -111,9°C (1 atm)

- Gas density: 2,144 g/l (0°C, 1 atm)

- Enthalpy of formation: 142,12 kJ/mol

- Solubility in water: 1370 mg/l (1 atm)

- Ozone O3, is the tri-atomic form of oxygen. In simple it is a molecule composed of three oxygen atoms.

- In nature, ozone is formed by reactions involving ultraviolet rays or by the electrical discharge of lighting.

- Behind fluorine and hydroxyl radicals, ozone has the third-highest oxidation potential at 2.07 (see chart below).

- Ozone O3 is 50 times more powerful and over 3000 times faster, acting than chlorine bleach. During its short “lifespan,” ozone is highly reactive.

- The third molecule in O3 is bonded loosely; it will break away, leaving pure oxygen, O2, and a single atom, O.

- Ozone is a high-energy molecule. Its half-life in water at room temperature is only 20 minutes, and it decomposes into simple oxygen.

- Because ozone can be produced on-site and on-demand, the effect is reduced chemical cost, storage, handling, and added plant safety.

- There are no toxic byproducts or potential health hazards when properly used as a microbicide,” said Myron Jones, EPRI Food Technology Center Manager. (Microbial contaminants include salmonella and giardia.)

OXIDATION POTENTIAL OF OZONE COMPARED TO OTHER OXIDIZERS

Ozone, or O3, is a powerful oxidizer widely used in various applications such as water treatment, food processing, and air purification. One of the key advantages of ozone is its high oxidation potential, which measures its ability to remove electrons from other substances and cause oxidation. Ozone has a relatively high oxidation potential compared to other common oxidizers, making it an effective and efficient option for many applications.

| Compound | Oxidation Potential | Relative power with respect to Chlorine |

|---|---|---|

| Fluorine | 3.06 | 2.25 |

| Hydroxyl Radicals | 2.80 | 2.05 |

| Ozone | 2.70 | 1.52 |

| Hydrogen Peroxide | 1.77 | 1.30 |

| Permanganate | 1.67 | 1.23 |

| Hypochlorous Acid | 1.49 | 1.10 |

| Chlorine | 1.36 | 1.00 |

This high oxidation potential of ozone means it can oxidize a wide range of contaminants, including bacteria, viruses, and organic compounds. It is also effective at removing odours and improving the overall quality of air and water. In water treatment applications, ozone is often used to oxidize organic compounds and other contaminants, helping to improve water quality and reduce the risk of waterborne illnesses.

OZONE GAS CHARACTERISTICS

- Invisible at normal concentrations

- It has a distinct pungent odour

- Heavier than air (vapor density =1.65; air =1.0)

- Decomposes to oxygen molecules

- Is the strongest commercial oxidant

- Is a stron disinfectant

- Can form HO radicals for AOP

- It has a residual short-lived; it converts to O2

- Is Generated On-site

IS OZONE HEAVIER THAN AIR?

Yes, ozone (O₃) is heavier than air. Its density is approximately 1.65 times that of air, meaning it tends to accumulate at lower levels when generated in enclosed spaces. This characteristic is important in industrial and safety applications, as proper ventilation helps prevent ozone buildup in areas where it could pose a health risk.

CHEMICAL REACTIONS OF OZONE IN WATER

When ozone is dissolved in water, it can undergo various chemical reactions. These reactions depend on pH, temperature, dissolved organic and inorganic substances, and ozone concentration. A significant concentration of ozone is required for effective chemical reactions in water. The most common chemistries of ozone in water are:

DIRECT REACTION

Ozone reacts directly with organic and inorganic compounds in water to form aldehydes, ketones, carboxylic acids, and peroxides. This reaction is rapid and typically occurs within a few seconds.

- Cycloaddition, electrophilic reaction, electron transfer, oxygen atom transfer

- Highly selective reactions with a wide range of organics and inorganics

INDIRECT REACTION

In this reaction, ozone reacts with water to form hydroxyl radicals (OH•). These radicals are highly reactive and can oxidize organic and inorganic substances in water. The reaction rate is slower than direct oxidation, and it requires the presence of dissolved organic and inorganic substances.

- Decomposition into HO° (E° = 2.80 V) on initiation

- Fast and unselective reactions

- Scavenging effect

OZONE FEED GAS

Ozone is generated using pure oxygen as the feed gas. This method is called “oxygen-fed” ozone generation, resulting in higher ozone concentrations than dry air as feed gas. Ultraviolet (UV) light at 185 nm can also be used to generate ozone. Using oxygen-feed gas is more efficient and cost-effective in applications where high ozone concentrations are required, such as in water treatment and industrial processes.

- The first step in generating ozone is creating concentrated oxygen to feed the ozone generator.

- On average, over 90% of all ozone equipment problems are due to poor-quality air or oxygen.

OXYGEN INFO

- makes up 20.94% (by volume) of the air we breathe

- Is colourless, odourless, & tasteless

- The most widely occurring element on earth

- The second-largest volume of industrial gas produced

- Forms compounds with all chemical elements except the nine noble gases

- Highly valued for its reactivity by itself & in its more reactive form, Ozone

HOW TO PRODUCE OXYGEN

- All systems utilize molecular sieves to perform the separation process

- The size of the sieve varies depending on the volume & pressure of air being separated

- The formula of the sieve varies depending on the function of the sieve

- The maximum purity that can be achieved with PSA & VPSA is 95.6%

METHODS OF OZONE GENERATION

- Ultraviolet (UV): Ultraviolet light at 185 nm generates a low concentration of O3.

- Corona Discharge: The most popular method for large and small applications. Used extensively for municipal water treatment

- Electrolysis: In-situ generation of ozone in water. Frequently used in high-purity water applications, cleanliness, and low dissolved oxygen is important.

- Plasma Block: The most effective, reliable, and economical method. Used in wastewater, bottled water plants, and others. Ozone can also be generated in the lower atmosphere through chemical reactions involving hydrocarbons and UV radiation.

OZONE CONTACTING SYSTEM

Factors Affecting Mass Transfer

- Gas-Phase Concentration

- Gas to Liquid Ratio (Vg/Vl)

- Pressure within the Contacting System

- Water Temperature

- Mixing (Gas/Liquid Interface Renewal): Turbulent circulation can mix things and affect the separation of components in the contacting system.

- Contact Time

- Instantaneous O3 Demand

OZONE OFF-GAS DESTRUCTION

- Thermal

- Catalyst

- Thermal/Catalytic

- Chemical

- Deliver Off-Gas to other use locations

OZONE SAFETY

- Materials of Construction

- Ventilation

- Safety Monitoring

- Exposure Limits

- Ozone Destructs

SAFETY OZONE ADVANTAGES

- Ozone is not stored in bulk on-site

- The catastrophic large-scale release is not likely because generator shutdown stops the ozone supply

- Ozone is not explosive or flammable

- leaks are identifiable – repair when they occur

- No reported fatalities from ozone exposure

IMPORTANT OZONE SAFETY CONCEPTS

- Automatic warning – You can smell ozone before it harms you

- Effects of ozone exposure are a function of time and concentration

- First aid

- Low-level exposure – get fresh air

- High-level exposure – seek medical attention

- Fix leaks when they occur

WHY USE OZONE?

- Oxidation of organic colour and odour compounds

- Microflocculation improves water clarity

- Reduced Chemical Consumption(residual sanitizer & pH)

- Improved Aesthetics

- Bather comfort (skin, eyes, hair)

- Reduced odours

- Superior disinfection protection

WHAT DOES OZONE DESCOMPOSE INTO?

Ozone (O₃) primarily decomposes into dioxygen (O₂) and a single oxygen atom (O). Under certain conditions, ozone can also react with carbon dioxide to form other compounds. Ozone readily decomposes into oxygen, making its half-life a crucial factor in determining its effectiveness in various applications.

EPA QUOTES ABOUT OZONE:

- Ozone is more effective than chlorine in destroying viruses and bacteria.

- The ozonation process utilizes a short contact time.

- No harmful residuals need to be removed after ozone because ozone decomposes rapidly.

- After ozonation, microorganisms are not re-growth except those protected by the particulates in the wastewater stream.

- Ozone is generated on-site, and thus, there are fewer safety problems associated with shipping and handling.

- Ozonation elevates the dissolved oxygen (DO) concentration of the effluent. The increase in DO can eliminate the need for re-aeration and raise the DO level in the receiving stream.