KEY FEATURES:

- Ozone acts as a strong oxidizing agent, supporting water quality management and sanitation processes.

- Ozone naturally reverts to oxygen after use, producing no residual taste or odor in treated water.

- Ozone is generated on-site, eliminating the need for chemical storage and minimizing handling requirements.

- When integrated into treatment systems, ozone can help reduce the reliance on additional chemicals and support operational efficiency.

OZONE FOR BOTTLED WATER

For over 50 years, ozone has played a key role in the bottled water industry as a widely adopted oxidation and water treatment technology. Ozonation has historically been implemented to support water quality management and process control within bottled water production facilities.

In the early development of the bottled water industry, maintaining consistent water quality during storage and bottling presented operational challenges. The introduction of ozone-based treatment systems helped address these challenges, establishing ozonation as a standard processing step in modern bottling operations.

The Advantages of Ozone for a Safe and Efficient Bottled Water Industry

Ozone is widely used in the bottled water industry as a reliable oxidation and water treatment method. When applied under properly controlled conditions, ozonation can contribute to the reduction of bacteria, viruses, and other contaminants as part of an integrated water treatment process. In bottled water production, ozonation is commonly implemented as a controlled processing step to support product quality, stability, and shelf-life management.

Today, some of the most critical contamination risks in bottling plants are associated with containers and the packaging line. Microorganisms, fungi, and even residues from cleaning agents can be present in these areas, leading to both chemical and biological contamination of the final product.

In recent years, concern over the presence of disinfection by-products—especially Trihalomethanes (THMs)—has grown significantly. THMs are classified as possible human carcinogens in Canada’s Drinking Water Guidelines, which set a maximum limit of 100 µg/L (micrograms per liter). Unlike chlorine-based treatments, ozone is generated on-site and breaks down into oxygen, leaving no harmful chemical residues or by-products behind. This makes ozone a safer alternative to chlorine, which can produce THMs and other undesirable compounds.

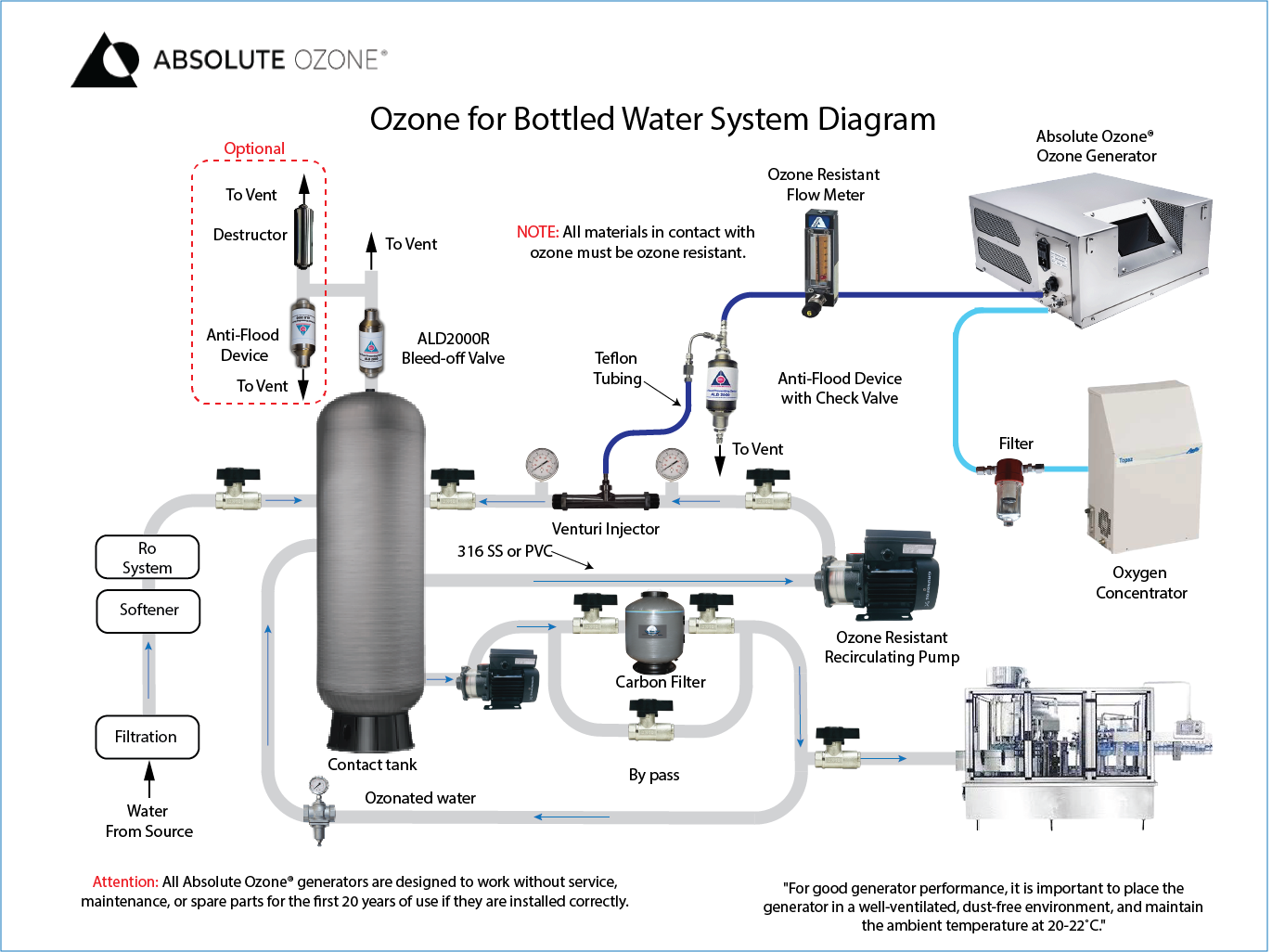

Ozone’s versatility adds value to the bottling industry through its integration into multiple stages of the production process. Under properly controlled operating conditions, ozone may be applied in water treatment and in the sanitation of bottle caps, containers, and filling equipment as part of an overall hygiene management strategy.

When correctly implemented, ozonation can support contamination control during production and handling, assist in maintaining controlled storage conditions, and contribute to the management of odors and sensory quality. In addition, ozone-based oxidation processes may assist in the reduction of certain disinfection by-products, such as THMs, and can help optimize cleaning procedures, potentially reducing energy consumption and improving operational efficiency.

Efficient and Effective Ozone Treatment Disinfection:

Ozone (O₃) is a powerful and fast-acting disinfectant widely used in the bottled water industry. Composed of three oxygen atoms, ozone is highly reactive, making it extremely effective at eliminating bacteria, viruses, and other contaminants from water. Its ability to purify large volumes of water in a short time makes it an ideal solution for high-throughput bottled water production.

Improved Taste and Odor

Beyond disinfection, ozone also enhances the sensory quality of water by removing unpleasant tastes and odors. This results in a cleaner, fresher taste that improves the overall drinking experience. In sparkling water production, ozone treatment can be used alongside carbon dioxide infusion to maintain a crisp and pleasant flavor.

Extended Shelf Life

By inhibiting the growth of microorganisms, ozone treatment helps extend the shelf life of bottled water. When used with purified water, ozone ensures that the product remains safe and stable over time, offering consumers fresh, high-quality drinking water whenever needed.

Cost-effective and Environmentally Friendly

Ozone is a cost-effective and sustainable water treatment method. It requires no added chemicals and has low operating costs. Often used in combination with reverse osmosis and other purification technologies, ozone enhances water quality while minimizing environmental impact. Because ozone is generated on-site and naturally decomposes into oxygen, it leaves no harmful residues—making it a clean and eco-friendly solution for the industry.

WHY ABSOLUTE OZONE®

We are one of the few manufacturers in the industry that guarantees the performance of our ozone generator. In addition, we eliminate any possibility of performance overstatement, which is sadly becoming more and more common in the ozone industry. Above all, we design to guarantee greater productivity. Our equipment requires practically no maintenance or spare parts.

Our goal is to provide an efficient and 100% reliable ozone generation system for your bottled water application and to provide customer service and support unmatched by our competitors.

With the Absolute Ozone® ozone generator, you can reduce your use of chemical products, lower costs, and achieve a successful return on investment for your company while improving your bottled water production.

Our higher ozone concentration and the unique design of the treatment system have excelled in beverage applications. As a result, several significant brands trust Absolute Ozone® generators to provide pure ozone for bottling applications as they seek efficiency and reliability.

OUR KNOWLEDGEABLE AND HIGHLY EXPERIENCED ENGINEERING TEAM WILL HELP YOU WITH:

- Selecting the Right Size Absolute Ozone® Ozone Generator for Your Ozone Bottling Application

- Supply the oxygen concentrator or help choose the correct oxygen supply by ensuring you have the proper air preparation/feed gas.

- Supply all necessary accessories, such as online monitoring and control equipment.

- Help with a complete initial design, installation guidance, and process details with maximum profitability.

- Provide full technical support from expert application engineers every step of the way, before installation and throughout the years.

Contact us now. Our staff will help you explore all the possibilities ozone can offer your project.