Ozone Library

Ozone Mass Transfer Beginners Guide

MASTERING THE FUNDAMENTALS OF OZONE MASS TRANSFER

Ozone mass transfer is the movement of a gas phase into water. In most Ozone applications, ozone needs to be dissolved into water. Ozone gas is partially soluble in the liquid. However, using proper methods and equipment high mass transfer efficiencies can be reached. Ozone can be transferred by either bubbling or mixing with a venturi mass transfer system.

INTRODUCTION

Initially, diffusion stones were the primary method for transferring ozone mass to water. Currently, venturi-based mass transfer systems are the preferred method for dissolving ozone in water due to their simplicity, economy, and effectiveness. In addition, a venturi injector has about 90% efficient and can be up to 99% efficient at dissolving ozone into the water.

VENTURI INJECTION

A venturi creates a negative pressure or vacuum by accelerating liquid through a narrowing constriction in a pipe or tube. A minimal differential in pressure between the inlet and outlet sides is enough to initiate a vacuum at the suction port. As a result of internal mixing vanes, thousands of micro-bubbles are created in Venturi injectors, greatly enhancing the surface area of ozone gas in contact with liquid.

In an integrated ozone system, the injector pump drives process water through the venturi, which creates a suction that draws in the ozone gas produced by the ozone generator.

The ozone gas vigorously mixes with the water flowing through the venturi, then passes downstream to the mass transfer vessel for secondary mixing and retention as needed for the specific application.

DESIGN CONSIDERATIONS

Some Venturi injectors are not made with materials resistant to ozone, so you should look for an ozone-resistant injector. We recommend Mazzei injectors because they have proven to be reliable and economical. An injection system must take into account the gas-to-liquid ratio and the pressure. The gas to liquid ratio refers to the volume of gas added to the volume of liquid. The less gas dissolved into liquid will inherently increase the solubility rate. We suggest a ratio of 1:10. The solubility of ozone gas into liquid is affected greatly by the pressure of the water. Higher pressures increase the solubility rate of ozone gas in the liquid.

Other important considerations:

- Venturi injectors’ outlets should be above their inlets (water flowing upward).

- Never restrict the Venturi outlet.

- Install pressure gauges directly at the Venturi inlet and outlet to verify water pressures

MASS TRANSFER VESSEL

To ensure a consistent supply of ozone-injected water to the process, applications with periodic stops and starts typically include a stainless steel mass transfer vessel. Indeed, the mass transfer vessel receives the ozone-injected water downstream of the venturi system to thoroughly mix the injected ozone gas and to vent undissolved gas from the vessel. The volume of the mass transfer vessel for a given application—which can range from 50 gals to hundreds and thousands of gallons—is a function of the demand and flow characteristics of the application.

Processes that operate continuously with few interruptions are best served with small mass transfer vessels of a few gallons to provide ozone and water mixing without a conventional tank. These systems are often referred to as tankless systems because they do not use a conventional large mass transfer tank.

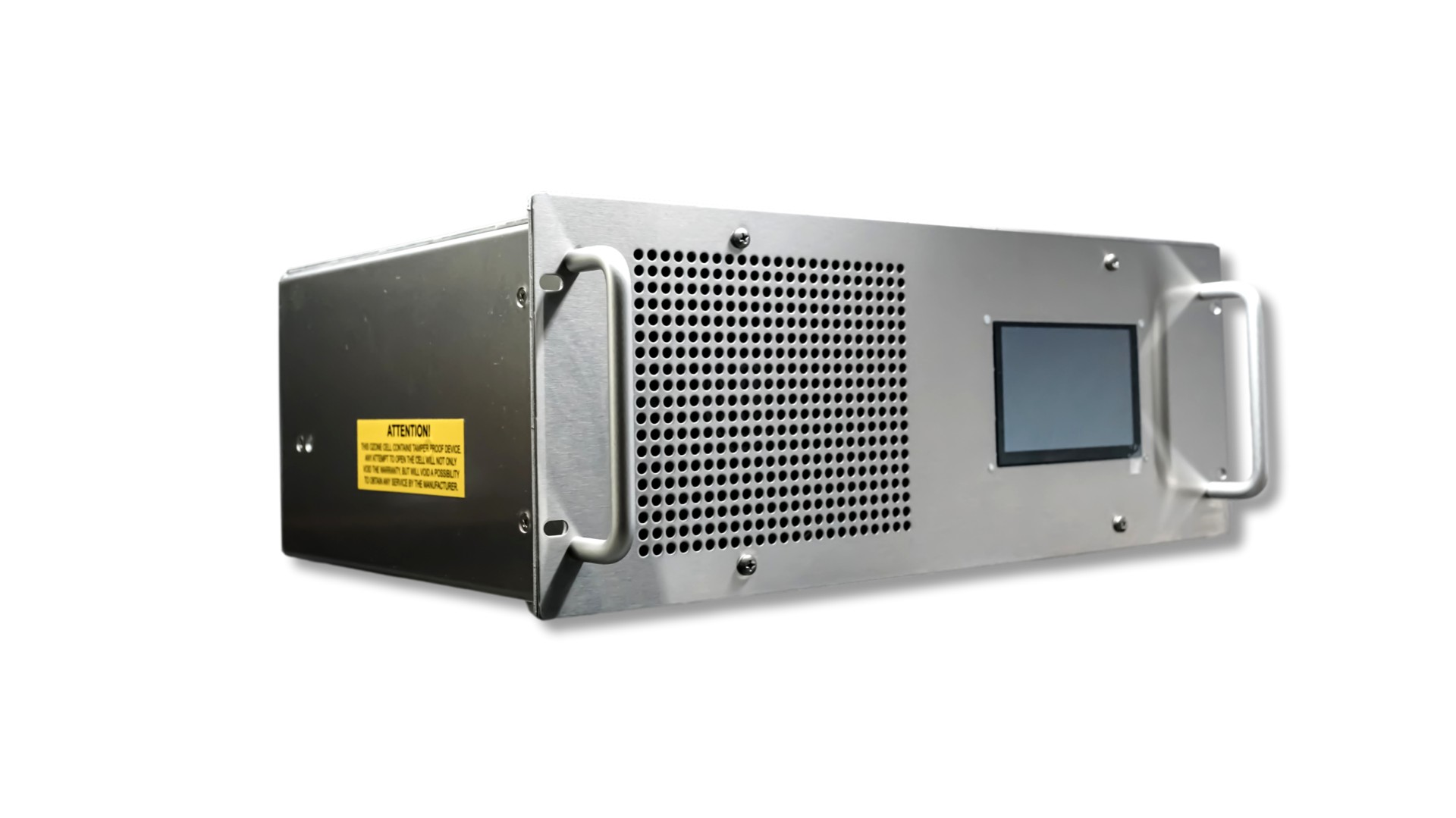

The undissolved gas vented from the mass transfer vessel and degas separation device is discharged through a destruct device, which contains a bed of heated catalyst that converts ozone gas back to diatomic oxygen and is then safely vented to the atmosphere.

OPTIMIZING MASS TRANSFER

The components and operating conditions of venturi-based mass transfer systems must be optimized to meet the needs of each application. A well-designed and optimized venturi-based mass transfer system will transfer up to 98% of the ozone gas into the solution.

The performance of the mass transfer system is reduced if the differential pressure does not support the gas volume to the venturi, resulting in a lower gas dose to the water. Mass transfer is affected by the gas-to-liquid ratio and pressure at the mixing zone at the discharge end of the injector into the mass transfer vessel.

Operation of an ozone system at an especially high vacuum may affect the ozone reactor cell and oxygen concentrator if the venturi suction exceeds the output of the ozone generator, limiting the efficiency of ozone generation and ultimately reducing the dissolved ozone concentration produced by the system.

To ensure safe system operation, the performance characteristics of the ozone destruct system (maximum flow rate and catalyst capacity) must match the potential output of ozone off-gas from the mass transfer vessel.

A truly functional mass transfer system requires careful consideration to match the performance of the various components to work well together and meet the overall requirements of the application.