Ozone Library

Benefits of Venturi Injection versus Bubble Diffusion in Commercial Laundry Systems

Over the last two decades, the ozone laundry industry has seen several companies rise and fall. Unfortunately, misleading claims and false information have become too common amid this growth. This post will analyze the design differences between two prominent ozone laundry systems: fine bubble diffusers and Direct Venturi Injection. We aim to present factual information and help readers make informed decisions about ozone laundry.

Design Differences: Fine Bubble Diffusion vs. Direct Venturi Injection

Ozone gas is dissolved into the water through a process known as “Mass Transfer.” The efficiency of Mass Transfer is highly dependent on the design of the ozone laundry device. Let’s explore the two major design approaches:

LET’S LOOK AT THE TWO MAJOR DESIGN DIFFERENCES.

Some ozone laundry companies use fine bubble diffusers, while others use Direct Venturi Injection. Some claim that both have advantages. Therefore, we should examine each design criterion and select the most suitable one.

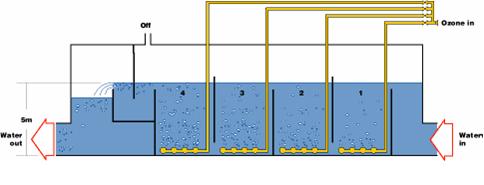

The concept of fine bubble diffusion injection, used in washing machines, is borrowed from the bottled water industry. Bottled water plants introduce ozone to large columns (or tanks) of water. These are usually over 15 feet tall. Water flows into the top of the tank and exits the tank through the bottom. The fine bubble diffuser is placed at the bottom of the tank. Ozone is introduced through the diffuser at the bottom of the tank. Water enters the tank at the top and flows downward, eventually exiting the tank at the bottom.

Due to the water counterflow, the ozone bubbles violently thrash as they rise. This turbulence facilitates a decent mass transfer of ozone gas into the water. The “Las Vegas” water treatment plant tanks are 32 feet tall. Remember that pressure is needed to transfer the ozone into the water solution. Every inch of the water column adds more pressure to the diffuser stone at the bottom of the tank. The taller the tank, the greater the pressure at the bottom. So, the greater the mass transfer of ozone in water.

Once the undissolved ozone reaches the top of the tank, it is removed through an air vent. Then, it is destroyed by passing through the ozone destruct system.

All in all, this is a safe and effective method for dissolving ozone into water.

Fine bubble diffusion systems designers implemented this system on a commercial laundry system. However, they left out a couple of key ingredients.

First, the water column in a washer is nowhere near that of a 32-foot-tall water tank. It is more like 12 inches. This allows for a much lower Mass Transfer efficiency of the ozone gas. Several ozone engineers have figured that the efficiency is somewhere in the 25-40% range at best. That means in the best-case scenario, 60% of the ozone gas does not get dissolved. This is important because 1% of undissolved ozone gas can easily make a room unsafe for the laundry workers.

You can capture and destroy this undissolved gas in the bottled water design. The main problem is that the designers overlooked this crucial component. Common sense tells you that if you force air into an unsealed vessel, air will escape. Some companies have attempted to conceal this major design flaw by installing an ozone monitor that theoretically shuts off ozone generators when a specific level is reached. The ozone generator only runs for a few seconds before shutting down due to the room’s ozone oversaturation. It then takes several minutes for the room sensor to reset and let the system turn the generator back on. I have witnessed the ozone generator operating for only 45 seconds during a 7-minute wash step. That’s not going to kill many “Super Bugs.”

In contrast, the Direct Venturi Injection system utilizes the pressure of the water stream in the piping to create suction. Applying suction at the appropriate port instantly dissolves 85-90% of the ozone gas into the water. The water and any remaining undissolved ozone can then pass through an Ozone Degassing chamber, where the undissolved ozone is removed and destroyed. This results in 100% dissolved ozonated water being delivered to the washing machine.

Although the Venturi Injection system may be more expensive to build, it offers several advantages. It ensures immediate ozone concentration, allowing for faster cleaning and sanitizing. Moreover, utilizing larger fill valves and water lines can significantly reduce wash cycle times, resulting in substantial time savings for commercial laundries.

WHY ARE THERE SO MANY BUBBLE DIFFUSERS IN THE INDUSTRY?

I recently attended an ozone conference. The guest speaker said a fine bubble diffusion system on a washer was “So easy to build that even a caveman could do it.” Not only is it easy to build, but it is also cheap to build this type of system. That is why there are so many on the market, and the low price keeps the attention of the potential uninformed buyer.

The Venturi Injection System uses the pressure of the water stream in the piping to create suction. When applied to this suction port, 85-90% of the ozone gas is instantly dissolved into the water. Since we still have water and undissolved gas inside the water piping, it can easily be run through an Ozone Degassing chamber, which removes the undissolved ozone gas, allowing it to be destroyed. The results show that 100% of the dissolved ozonated water is directed to the washing machine.

This is an oversimplification of the process. However, it should get the point across without going into all the hydraulic engineering facts that make this a much more reliable and stable method for dissolving ozone into water.

Another reason not to consider the fine bubble diffusion type of technology is the time it takes to build up to concentration. Those of you operating commercial laundries know you never want to fill a washer with cold water and steam up the temperature to 160 degrees because it takes too long. I am aware that there are some instances where this is unavoidable. However, typically, you would fill your washer with standard hot water, usually 130-140 degrees, and then add steam injection to raise the temperature in those wash steps where a slightly higher temperature is required.

The same is true with the fine bubble diffuser. A Venturi Injection system instantly fills the washer with highly concentrated ozonated water, starting the cleaning and sanitizing process. A fine bubble diffusion system can take 20 minutes to reach the ozone levels at which the Venturi Injection system begins. None of us has that much extra time available in our wash cycle.

Some markets use Venturi Injection Systems to utilize larger-than-normal fill valves and water lines. This will enable significantly faster fill times. I have witnessed a 60 lb washer/extractor being filled in under 25 seconds, whereas the standard fill time was over 2 minutes. A standard hospitality wash cycle with five fills would reduce your total operating time by more than 7 minutes. Washing an average of ten loads per day, this type of ozone laundry system would easily eliminate over one hour of processing per day.

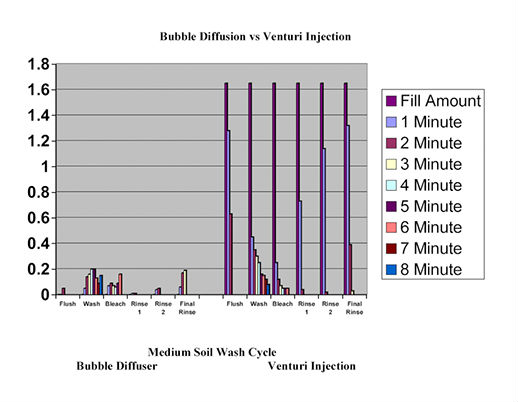

In the graph below, you can see two identical tests that show ozone concentration during a complete wash cycle. Notice in the Venturi Injection System, the levels start high and slowly dissipate before the water is drained in each bath. You should also notice the effect of PH on each bath in the wash cycle. During the detergent and bleach steps, the ozone is reduced as the higher PH from the wash chemistry counteracts it. As the detergent and bleach are rinsed out, you can see that the ozone hangs around much longer.

In the fine bubble diffuser, you will notice that the ozone levels never reach above 0.2 PPM of ozone in the water. It is also evident that the higher PH makes it hard for the ozone to overcome when using a Fine Bubble Diffuser.

I am not stating that the fine bubble diffusion system does not work or does not clean laundry, but rather, it is nowhere as effective as a properly designed Venturi Injection System. Results will be more consistent with the Venturi Injection System than a comparable Fine Bubble Diffusion System.