Ozone Library

Hydrogen Sulfide Removal with Ozone: A Comprehensive Approach

Introduction:

Hydrogen sulphide contamination in groundwater is prevalent, marked by its distinct rotten eggs’ odour and an alarming threshold of 0.0011 mg/l (1). Besides the unpleasant smell, hydrogen sulphide can impart a characteristic and undesirable taste to water. Aeration is a standard method to strip hydrogen sulphide from water, but it poses the risk of transforming a water problem into an air pollution problem without proper additional treatment. This article explores the efficacy of Ozone in removing hydrogen sulphide and outlines essential design considerations for an efficient and sustainable water treatment system.

Ozone Oxidation Process:

Hydrogen sulphide’s oxidation with Ozone is a well-established method for forming sulphate. The initial oxidation results in elemental sulphur appearing as a light-coloured colloidal suspension. Subsequent oxidation processes dissolve the elemental sulphur into sulphite, with continued oxidation producing sulphate. It is crucial to note that more Ozone is required to convert hydrogen sulphide to sulphate than sulphur.

Design Considerations:

To effectively remove hydrogen sulphide, careful consideration must be given to the design of the ozone treatment system. The theoretical dose ratio for Ozone sulphate oxidation is 3:1. Still, practical applications often require a ratio of 4:1. This results in a small ozone residual in the water, typically ranging from 0.2 to 0.3 ppm. This residual acts as a buffer, guaranteeing the complete removal of hydrogen sulphide.

In cases where hydrogen sulphide concentration varies, monitoring the ozone residual allows for real-time adjustments in the dosage rate, ensuring consistent and thorough removal. When using fine bubble diffusers and a multi-chambered contact vessel, injecting Ozone only into the first chamber is crucial. Injecting Ozone into later sections can lead to off-gas stripping of hydrogen sulphide, potentially fouling the catalyst responsible for neutralizing excess Ozone in the off-gas. The right injection point is critical to a prolonged (2-year) catalyst lifetime.

Absolute Ozone Technical Support:

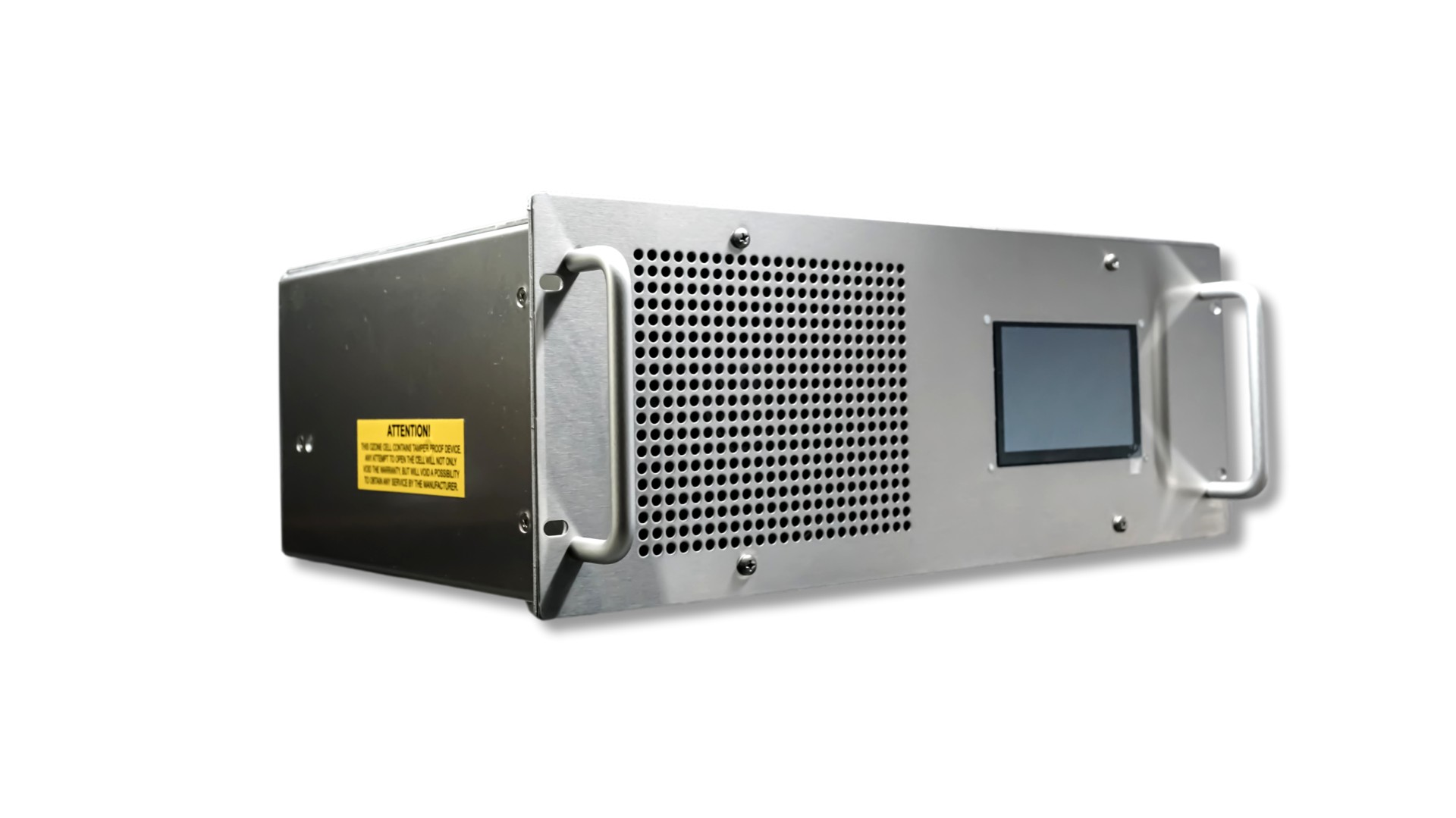

Implementing an ozone-based system for hydrogen sulphide removal requires expertise and precision. Absolute Ozone provides state-of-the-art ozone generators and equipment for water and air treatment applications and technical support. Their experienced team assists in correct system sizing and installation, ensuring optimal performance and longevity. If you need additional information or assistance, please contact us now.

Conclusion:

Hydrogen sulphide removal with Ozone presents an effective solution to address groundwater contamination issues. Water treatment systems can achieve optimal results by understanding the intricacies of the oxidation process and incorporating thoughtful design considerations. Absolute Ozone’s commitment to providing quality equipment and technical support further enhances the feasibility and success of ozone-based hydrogen sulphide removal systems.

1 Wang, Lina, et al. “Construction of Salicylaldehyde Analogues As Turn-on Fluorescence Probes and Their Electronic Effect on Sensitive and Selective Detection of As(<Scp>V</Scp>) in Groundwater.” Analytical Methods, 2019, https://doi.org/10.1039/c8ay02484g.