Ozone Library

Ozone Water Waste Treatment Plant: A Modern Solution for Cleaner Water

Introduction: Why Wastewater Treatment is Essential

Wastewater treatment, or sewage treatment, is a critical environmental challenge worldwide. With urbanization and industrial growth, finding effective and sustainable methods to treat wastewater and ensure high-quality water has become increasingly necessary. Failing to treat wastewater properly can result in severe pollution, threatening public health and damaging natural ecosystems.

Municipal wastewater treatment is essential in urban areas, where the prevalence of untreated sewage can lead to significant environmental and public health issues. Proper municipal wastewater treatment processes prevent water pollution and protect public health.

Ozone wastewater treatment plants are an innovative technology that has gained attention for their efficiency and eco-friendliness. This method guarantees high-quality treated water and minimizes the environmental impact, making it a cutting-edge solution for the future of water management.

What is Wastewater?

Wastewater is water that has been used and contains contaminants, requiring treatment before it can be safely released into the environment. It originates from a variety of sources:

- Domestic Wastewater: Generated from households and includes contaminants like food waste, soaps, and chemicals.

- Industrial Wastewater: Contains complex pollutants, heavy metals, and hazardous chemicals.

- Agricultural Runoff: Enters the water system from fields and farms, often carrying pesticides, fertilizers, and organic waste.

- Stormwater: Rain runoff that can carry pollutants from streets and pavements into the treatment system.

Sewage treatment plants are essential for managing industrial and domestic wastewater, which undergoes various treatment processes to remove contaminants and prevent environmental pollution.

Importance of Wastewater Treatment Plants

Wastewater treatment plants play a crucial role in protecting water quality and public health by removing impurities and contaminants. These facilities use physical, chemical, and biological methods to ensure that water is treated to high-quality standards before discharge or reusing. The main stages of treatment include:

- Primary Treatment: Removes large suspended solids.

- Secondary Treatment: Uses biological processes to degrade organic matter.

- Tertiary Treatment: Targets any remaining pollutants to ensure water meets safety standards.

Treating wastewater prevents pollution, conserves water resources, and supports the sustainable use of water in industrial and agricultural processes.

Ozone Water Treatment: An Advanced Approach

What is Ozone Water Treatment?

Ozone water treatment is a technology that utilizes the powerful oxidizing properties of ozone gas (O₃) to break down organic and inorganic contaminants. Unlike traditional methods, ozone treatment does not produce harmful byproducts. The ozone rapidly decomposes into oxygen (O₂), making it an environmentally friendly option for water purification.

How Do Ozone Wastewater Treatment Plants Work?

- Pretreatment: Incoming wastewater undergoes initial screening and filtration to remove solid waste and large particles. Centralized sewage treatment plants play a crucial role in managing large quantities of sewage in densely populated areas, utilizing a combination of physical, biological, and chemical processes to treat wastewater before discharge effectively.

- Ozonation: The pretreated water is introduced into a specialized ozone reactor. Ozone is generated on-site using a high-voltage ozone generator and injected into the water. The contact between ozone and water oxidizes pollutants, including volatile organic compounds (VOCs), heavy metals, and chemicals.

- Disinfection: Ozone is a highly effective disinfectant that destroys bacteria, viruses, and other pathogens without leaving toxic residues.

Benefits of Using Ozone in Wastewater Treatment

- High Efficiency in Pollutant Removal: Capable of treating a wide range of contaminants, including hard-to-remove chemicals.

- No Harmful Byproducts: Unlike chlorination, ozone does not produce harmful byproducts such as trihalomethanes (THMs).

- Environmentally Friendly: Ozone is generated from oxygen and decomposes into oxygen, leaving no lasting residue.

- Faster and More Effective Disinfection: Ozone acts quickly and effectively even at low concentrations.

Applications of Ozone Wastewater Treatment

Ozone treatment plants are suitable for a variety of applications, including:

- Municipal Water Treatment: Ensures safe drinking water for communities.

- Industrial Effluent Treatment: Removes complex pollutants from manufacturing and chemical processes.

- Groundwater Remediation: Treats contaminated groundwater by breaking down pollutants.

- Gray Water Recycling: Makes wastewater reusable for non-potable purposes such as irrigation.

- Food and Beverage Production: Ensures water used in production meets high safety and quality standards.

The Environmental Protection Agency (EPA) regulates these facilities to guarantee their safe and effective operation and to protect human health and the environment.

Wastewater Treatment Plant Design

Designing a wastewater treatment plant is a meticulous process that ensures the effective and efficient treatment of wastewater. The design must consider the type and quantity of wastewater to be treated, the specific treatment processes employed, and the environmental and regulatory requirements to be met. A well-thought-out design is crucial for the plant’s overall performance and sustainability.

Design Considerations for Ozone Integration

Integrating ozone treatment into a wastewater treatment plant requires careful planning and consideration of several key factors:

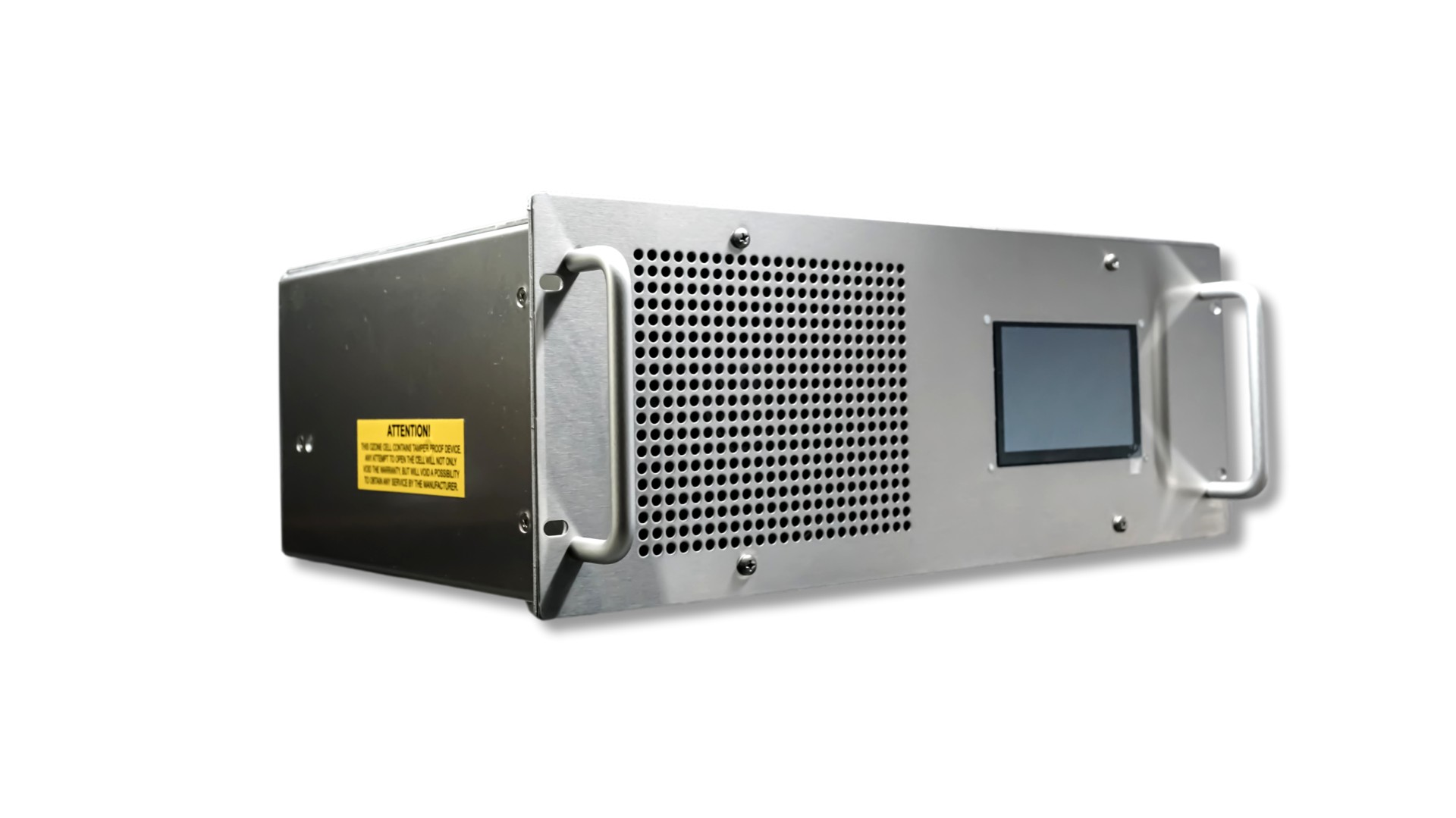

- Ozone Generators: Our team of experts will help you select the appropriate ozone generators to meet your treatment needs. These generators must produce sufficient ozone to handle the volume and type of contaminants present in the wastewater.

- Ozone Contact Tank and Mixing System: The design of the ozone contact tank and the mixing system is critical for ensuring effective contact between ozone and contaminants. Proper mixing ensures that ozone is evenly distributed throughout the water, maximizing its oxidizing potential.

- Materials of Construction: The materials used in the ozone contact tank and piping must resist ozone’s corrosive properties. This ensures the system’s longevity and reliability.

- Monitoring and Control Systems: Implementing advanced monitoring and control systems helps maintain optimal ozone dosage and treatment efficiency. These systems can automatically adjust ozone levels based on real-time data, ensuring consistent and effective treatment.

A well-designed ozone treatment system enhances the efficiency of the wastewater treatment process and minimizes the risks associated with ozone use, ensuring a safe and sustainable operation.

Wastewater Treatment Plant Operations

The day-to-day operations of a wastewater treatment plant are crucial for maintaining its efficiency and effectiveness. Operators must manage the treatment process, perform regular maintenance, and ensure compliance with environmental and regulatory standards. Effective operations are critical to the plant’s success and longevity.

Operational Best Practices for Ozone Treatment

Operating a wastewater treatment plant that incorporates ozone treatment involves several best practices to ensure optimal performance and safety:

- Regular Monitoring: Continuously monitoring ozone dosage and treatment efficiency is essential for optimal performance. This involves using sensors and control systems to track and adjust ozone levels as needed.

- Maintenance: Regular maintenance of ozone generators and other equipment is crucial for reliable operation. This includes routine inspections, cleaning, and replacing worn parts to prevent breakdowns and ensure consistent performance.

- Safety Procedures: Implementing comprehensive safety procedures minimizes the risks associated with ozone use. This includes proper handling and storage of ozone, as well as emergency response protocols in case of leaks or equipment malfunctions.

- Operator Training: Thorough training on the safe and effective use of ozone treatment is essential. Well-trained operators are better equipped to manage the system, troubleshoot issues, and ensure compliance with safety standards.

- Continuous Improvement: Regularly evaluating the treatment process and identifying opportunities for improvement helps enhance efficiency and effectiveness. This can involve adopting new technologies, optimizing existing methods, and implementing feedback from operators and stakeholders.

By adhering to these best practices, wastewater treatment plant operators can ensure that the ozone treatment system operates safely and effectively, meeting environmental and regulatory requirements while providing high-quality treated water.

Wastewater Treatment Plant Safety

Safety is paramount in wastewater treatment plants, particularly those utilizing ozone treatment. Ensuring the health and well-being of plant operators and the surrounding community involves identifying and mitigating hazards, implementing safety protocols, and providing comprehensive training.

Ensuring Safety in Ozone Treatment Facilities

Working with ozone treatment facilities presents unique safety challenges that must be addressed to protect personnel and the environment:

- Ozone Exposure Risks: Ozone exposure can cause respiratory problems and skin irritation. To prevent harmful exposure, monitoring ozone levels and ensuring proper ventilation is crucial.

- Electrical Safety: Ozone generators and related equipment operate at high voltages, posing a risk of electrical shock. Proper insulation, grounding, and regular maintenance are essential to mitigate this risk.

- Ventilation and Emergency Shutdown: Ensuring adequate ventilation in areas where ozone is used helps disperse accidental releases. Emergency shutdown procedures must be in place to quickly stop ozone generation in case of a malfunction.

- Regular Maintenance and Inspection: Routine maintenance and inspection of equipment help identify potential issues before they become serious problems. This proactive approach ensures the reliability and safety of the treatment system.

By addressing these safety considerations and implementing robust safety protocols, wastewater treatment plant operators can create a safe working environment, protecting themselves and the community while ensuring effective wastewater treatment.

Environmental Impacts of Wastewater Treatment

If not appropriately operated, wastewater treatment plants can negatively impact the environment. Issues like the discharge of untreated or partially treated wastewater can harm aquatic life, contaminate drinking water sources, and pose significant health risks. The treatment process can generate greenhouse gases and consume large amounts of energy.

Modern Solutions for Reduced Environmental Impact

- Advanced Biological Nutrient Removal: Efficiently removes excess nutrients to prevent eutrophication in water bodies.

- Energy-Efficient Technologies: Use high-efficiency pumps, motors, and other equipment to minimize energy consumption.

- Incorporation of Renewable Energy Sources: Solar panels, biogas production, and hydropower help reduce carbon footprints.

- Optimized Operational Processes: Automation and intelligent technology reduce water losses and improve efficiency.

Energy Efficiency in Wastewater Treatment

Energy consumption is a critical consideration for wastewater treatment plants. These facilities often require large amounts of energy, contributing to greenhouse gas emissions and operational costs. Strategies to improve energy efficiency include:

- Use of High-Efficiency Equipment: Upgrading to energy-efficient pumps, blowers, and motors.

- Implementation of Renewable Energy: Incorporating solar, wind, or biogas to offset energy needs.

- Process Optimization: Utilizing automated controls and monitoring systems to optimize energy use.

Conclusion:

The Future of Sustainable Water Management

Ozone wastewater treatment plants represent a sustainable and efficient approach to water management challenges. As demand for cleaner and safer treatment solutions grows, ozone technology is becoming a key player in protecting human health and the environment.

Key Takeaways:

- Ozone water treatment is highly effective and environmentally friendly.

- Modern wastewater treatment plants use a combination of physical, chemical, and biological processes to ensure safe water discharge or reuse.

- Energy efficiency and reduced environmental impact are priorities in the design and operation of treatment facilities.

By adopting advanced technologies and sustainable practices, ozone treatment plants contribute to a future with cleaner and safer water for all.