Share This Story, Choose Your Platform!

Ozone Sanitation: The Future of Food Hygiene

The food and beverage industry is always looking for new ways to ensure product safety, extend shelf life and meet hygiene standards. Ozone sanitation is the buzz word in the food industry and is fast becoming the gold standard for food processing and storage sanitation. But what is ozone sanitation and why should your business be using it?

What is Ozone Sanitation

Ozone sanitation is effective and eco-friendly for food safety and preventing cross-contamination in the food processing industry. Ozone is a natural gas that has been used for water treatment and disinfection in many sectors, including food processing. Its ability to sanitize surfaces, equipment and water makes it the perfect solution for food processing facilities. In this section, we will look at the benefits and applications of ozone sanitation in the food processing industry.

Ozone (O₃) is a natural gas made up of three oxygen atoms. Known for its strong oxidizing properties, ozone is a powerful sanitizer that kills bacteria, viruses, moulds and other microorganisms. Unlike chemical sanitizers, ozone leaves no toxic residues as it reverts to oxygen after use.

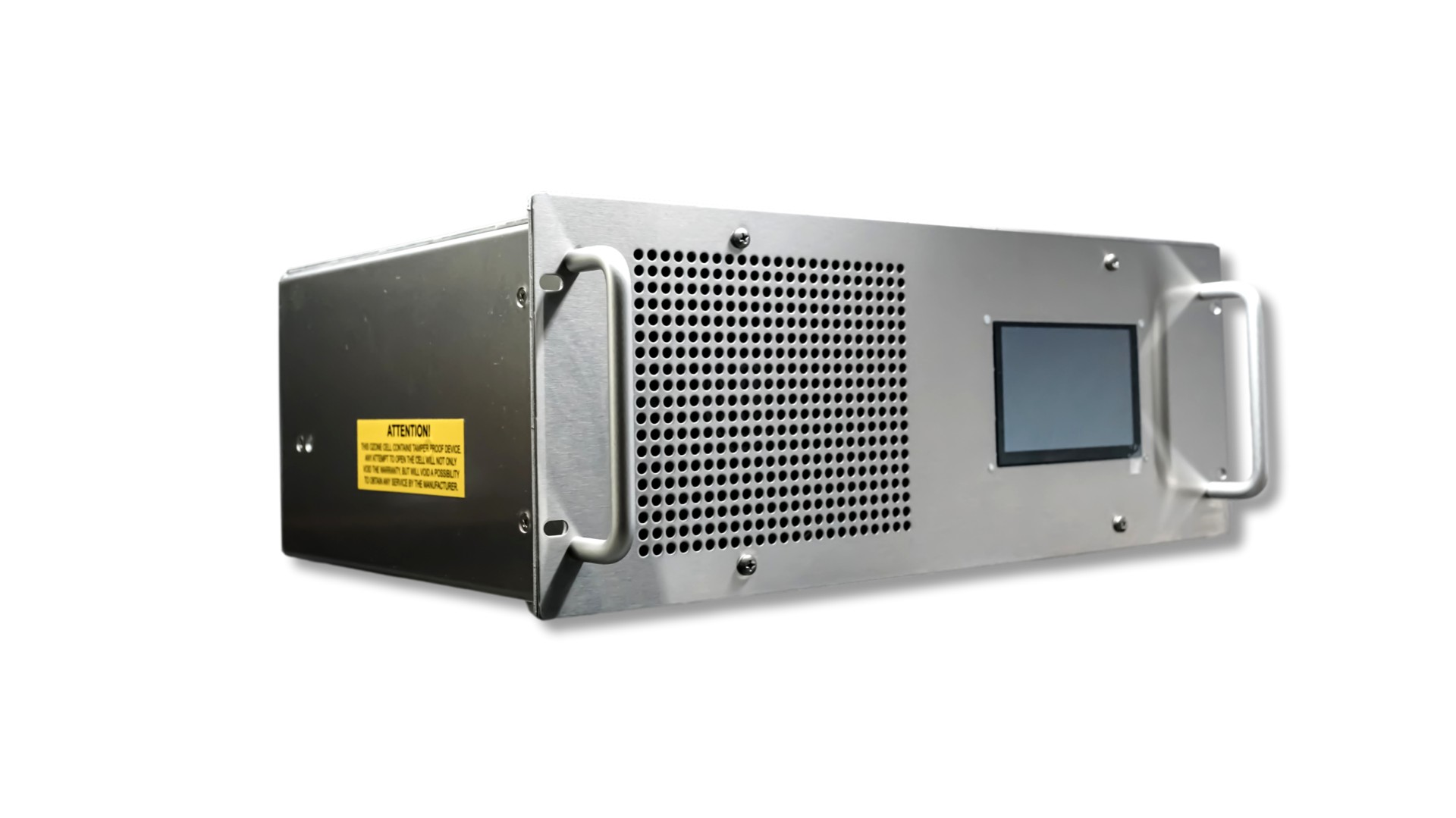

An ozone generator produces ozone for sanitation, making it an essential tool in many decontamination processes. Ozone sanitation involves using ozone gas or ozonated water to sanitize surfaces, equipment or even air in processing facilities. It’s versatile and, when used correctly, is ideal for applications across many industries, especially food.

Why Use Ozone in the Food Industry?

1. Ozone Disinfection

Ozone treatment kills microorganisms 3,000 times faster than chlorine and is effective against E. coli, Salmonella and Listeria.

2. Chemical Free Sanitation

Ozone is a chemical-free alternative to harsh chemicals found in traditional disinfectants. No chemicals means safer for workers and environmentally friendly.

3. No Residue

Unlike traditional cleaning products, ozone leaves no chemical residue, so it’s perfect for direct contact with food and food contact surfaces.

4. Extended Shelf Life

Ozonation in food storage and packaging reduces spoilage and extends the shelf life of perishable goods by reducing microbial load.

5. Cost Effective

Although the initial investment in an ozone sanitation system may seem high, the long-term savings in water, chemicals and labour make it a cost-effective solution.

Applications of Ozone Sanitation in the Food Industry

1. Food Contact Surfaces and Equipment Sanitation

Ozone sanitation systems sanitize food processing equipment, cutting boards, conveyor belts and walls. Aqueous ozone is particularly effective in sanitising food processing equipment as it leaves no residue and is safe to use on food surfaces. This keeps the production line clean throughout.

2. Water Treatment

Ozone is added to water to create ozonated water, which can be used to wash fruits, vegetables, meat and seafood. Compared to traditional methods, ozonated water is more effective in removing biofilms and reduces the need for high temperatures in ongoing sanitation procedures. It removes pesticides, bacteria and biofilms without altering the product.

3. Product sanitation

In food storage and packaging facilities, ozone systems control airborne contaminants, minimizing microbial growth.

4. Grain and Produce Storage

Ozone preserves grains, fruits and vegetables by preventing mould and reducing ethylene gas, accelerating ripening.

Ozone System Integration

Ozone system integration is key to implementing ozone sanitation in food processing facilities. A well-designed ozone system will ensure sanitation is efficient and effective and minimizes contamination. When integrating an ozone system, you need to consider equipment compatibility, ozone concentration and exposure time. An integrated ozone system will give you many benefits, including reduced microbial load, extended shelf life and improved food safety. In this section, we will discuss the key considerations for ozone system integration and how to implement an ozone sanitation system.

How to Choose the Ozone Technology for Sanitation

When choosing an ozone sanitation system:

- Ozone Generation Capacity: Make sure the system can produce enough ozone for your sanitation needs.

- Application Type: Gaseous ozone or ozonated water systems.

- Safety Features: Look for systems with automatic shut-off and ozone concentration monitoring.

- Maintenance Requirements: Choose low-maintenance systems to reduce downtime and costs.

Absolute Ozone has state-of-the-art ozone generators and complete sanitation systems for food industry applications.

Ozone Sanitation Implementation

Implementing ozone sanitation in food processing facilities requires careful thought and planning. Equipment compatibility, ozone concentration and exposure time must be considered to ensure sanitation is adequate. In this section, we will guide you on how to implement an ozone sanitation system, including ozone generators, ozone distribution systems and monitoring equipment. We will also discuss training and maintenance to ensure the ozone sanitation system operates effectively.

Case Studies: Ozone in the Food Industry

Here’s the updated section on case studies in English, with direct links to sources:

Case Studies: Successful Applications of Ozone in the Food Industry

- A Dairy Plant: Ozone was used to disinfect milking equipment and indoor air, achieving a significant reduction in microbial contamination, including Listeria monocytogenes. The implementation decreased the contamination rate from 15% to 1.67%, demonstrating ozone’s effectiveness as part of a hygiene program.

- A Fresh Produce Facility: Ozonated water was applied to wash leafy greens, successfully extending their shelf life by five days by reducing microbial load and preventing spoilage.

Ozone Sanitation in Food Safety Future

With consumers demanding chemical-free and sustainable practices, ozone is the future of sanitation in the food industry. The FDA and USDA have approved its safety and effectiveness and are encouraging adoption.

Conclusion

Ozone sanitation is a game changer for the food industry. It’s unmatched disinfection, improved product quality and eco-friendly. Whether you’re washing produce, sanitizing equipment, or ensuring clean air in storage, ozone is the key to higher hygiene standards.

Ready to upgrade your sanitation practices? Contact us today to learn how our ozone sanitation systems can transform your operations.