KEY FEATURES:

- Ozone largely eliminates mycotoxins and pathogens.

- Ozone does not leave residues.

- Ozone saves money over a longer period of time than any other alternative.

- Ozone is “GRAS” for use in food processing.

- lower bacterial levels

- Safe for the environment

- Improve water quality and reduce water usage

OZONE FOR FOOD SAFETY AND SANITATION

The food industry has strict quality controls and standards to satisfy consumers and comply with regulations. All sanitation systems are designed to maintain safety and microbial control. But not everyone can offer a highly efficient, safe, environmentally friendly, low maintenance, and low-cost disinfection system. Ozone for food safety and sanitation can!

Introduction

It isn’t easy to understand why food processing applications still widely use chlorine as a commercial disinfectant agent. The list of chlorine drawbacks is enormous. Chloride is inefficient; It has a limited effect on its ability to kill common food bacteria and cannot reduce levels of organic compounds. Chloride is unsafe or environmentally friendly; Chloride is risky due to the by-product formation/accumulation and the negative impact of chlorine in discharged water. Chlorine is not an economical solution; it has a high cost in the excessive use of chemicals and indirect expenses related to handling and storage. In addition, it leaves residues that can change food properties, affect the quality, and a significant amount of water needed for the rinse stages.

Ozone food safety and Sanitation are ideal substitutes for chlorine. In fact, it is more effective than chlorine against microorganisms. Ozone Treatment can also destroy chlorine by-products, pesticides, and toxic organic compounds in process water without leaving dangerous residue. Moreover, Ozone is safe; The USDA and FDA approved using ozone for direct contact with food products, and it is recognized as GRAS (Generally Recognized as Safe). Also, Ozone is economic; It has a lower running cost and low maintenance. We have Absolute Ozone® Generators in the field, working without maintenance, service, or spare parts for over 17 years. Finally, Ozone reverts to oxygen, leaving no harmful chemical residuals or altering the taste of treated food.

The Benefits of Using Ozone for Sanitization

Ozone (O3) has become an increasingly popular choice for sanitizing in the food industry. Ozone is used to disinfect food contact surfaces and processing equipment as it is a safe and eco-friendly alternative to traditional chemical disinfectants. Unlike other disinfectants, gaseous Ozone breaks into oxygen within a few minutes after use, leaving no toxic residue or harmful by-products. In addition to being safe, Ozone is also highly effective. Its strong oxidizing effect can eliminate even the most resistant pathogens, making it ideal for food applications.

Ozone is recognized as a safe and effective alternative to traditional chemical sanitizers such as chlorine, iodine, and ammonium compounds. Using Ozone for sanitization can help food processors comply with regulations for food safety and Sanitation. It can help to ensure that food processing equipment and surfaces are free from harmful microorganisms that can cause foodborne illness. Ozone can also help to extend the shelf life of fresh produce by inhibiting the growth of mold and other microorganisms, reducing food waste, and improving overall food safety.

ABSOLUTE OZONE® for food safety and sanitization

The food and beverage industry uses Absolute Ozone® equipment worldwide. For more than 25 years, we have ensured that the concentration and reaction time are correct for each process. Our Absolute Ozone® systems have been delivering excellent results being an economical and effective disinfection method.

Our engineering team can provide valuable support and expertise for businesses looking to incorporate ozone technology into their dairy applications. We will help you with the following:

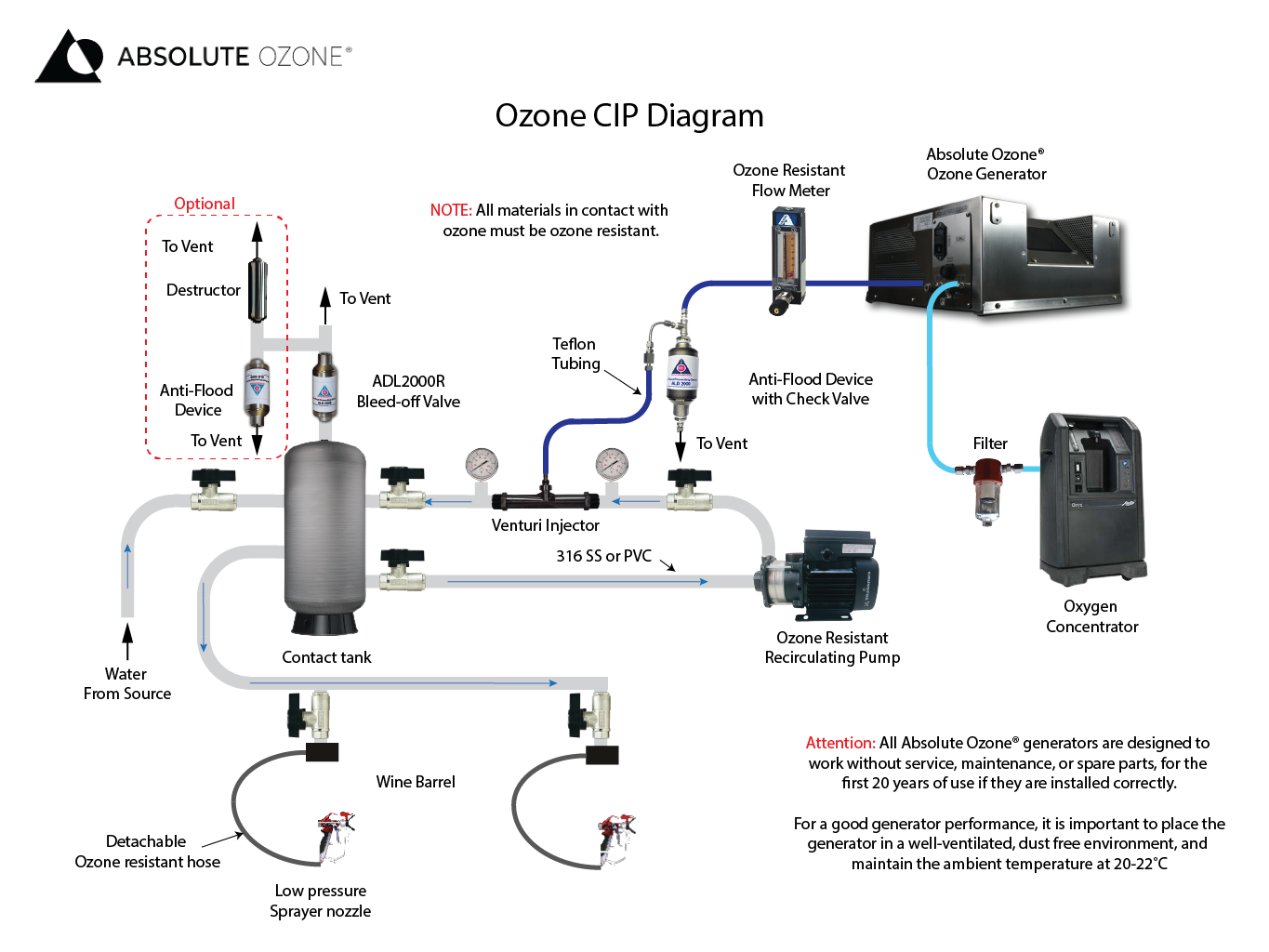

- Selecting the Right Size Generator: We can help businesses determine the appropriate size of Absolute Ozone® Ozone Generator needed for their specific application.

- Oxygen Supply: This ensures the air preparation and feed gas are correctly configured for optimal performance.

- Supplying Necessary Accessories: To ensure a fully functional ozone system, including online monitoring and control equipment.

- Initial Design and Installation Guidance: This is important to maximize profitability and efficiency.

- Technical Support: Once the ozone system is installed, We can provide ongoing technical support from expert application engineers to ensure optimal performance and troubleshoot any issues.

Absolute Ozone® generators are the most efficient in the industry and are backed by a 5-year performance and quality guarantee.