KEY FEATURES:

- Ozone technology eliminates mycotoxins and pathogens in meat products.

- Ozone does not leave residues.

- Ozone saves money over a longer period of time than any other alternative.

- Ozone is Generally Recognized as Safe (GRAS) for use in food processing.

- Ozone is effective in killing bacteria and pathogens

- Ozone is a powerful and versatile tool for food processors

OZONE GENERATOR FOR MEAT DISINFECTION

The meat industry faces significant challenges in ensuring the safety and quality of its products. Bacterial contamination, spoilage, and other issues can lead to consumer health concerns and result in economic losses for producers in the beef industry.

Meat is an ideal medium for the growth of microorganisms and spreading bacteria. Meat is highly susceptible to pathogens, including Salmonella, listeria, and E. coli. The pathogens live naturally in the intestine and can become contaminated during transport, slaughter, and production. Cross-contamination between food processing equipment is a major problem in the food industry. Food contact surfaces, such as cutting boards and knives, can become contaminated with pathogenic microorganisms during meat processing and handling. Contamination of these surfaces can lead to the transfer of microorganisms to the meat, increasing the risk of foodborne illness.

In addition, to the risk of contamination during production, transport, and cold storage, meat is highly perishable due to its high protein and moisture content. This makes it more susceptible to spoilage and degradation.

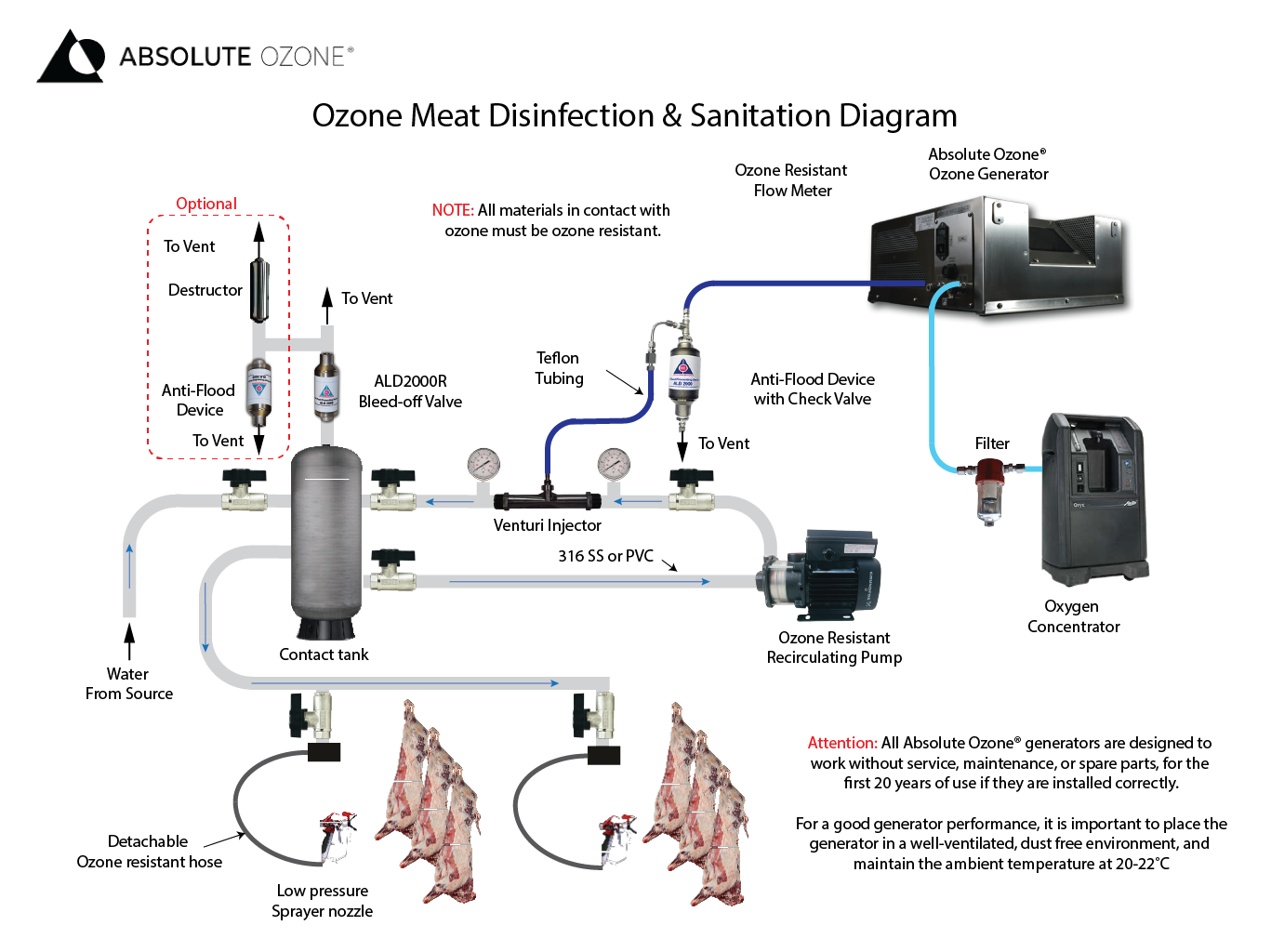

Therefore, it is imperative to use effective disinfection methods to control contamination in meat and reduce the risk of foodborne illnesses. Proper hygiene practices and disinfectants such as ozone can help mitigate the contamination risks in meat products. Ozone technology for meat disinfection offers a great solution. Additionally, ozone can be used to control airborne contaminants in meat processing environments, maintaining indoor air quality and preventing cross-contamination from airborne pathogens

The Power of Ozone Disinfection

Salmonella is the most commonly associated pathogen with poultry products. Currently, contamination is removed or controlled during carcass processing using a combination of thermal treatment, water, and chemical antimicrobials, such as peracetic acid (PAA). However, these chemical antimicrobials can be toxic before and after oxidation. Additionally, these chemicals affect meat quality because they produce undesired color and texture effects and the development of off-flavors. In addition, chemical antimicrobials are expensive and have the disadvantage of leaving hazardous residues.

The food industry is turning to ozone to lower sanitation and disinfection costs. Ozone is a potent and safe disinfectant, with 1.5 times the power of chlorine and 3000 times the reactivity. Studies have shown that ozone is effective against common meat microorganisms, parasites, and viruses, including Salmonella, mesophilic, and Escherichia coli. Gaseous ozone is used in treating meat products to kill bacteria such as E.coli and Listeria monocytogenes, improving beef quality and prolonging shelf life during refrigerated storage. Ozone

Ozone is a bactericidal agent with a rapid inactivation mechanism, and it does not leave residues, making it a safe and economical disinfection solution. For instance, treating carcasses with ozonized water can reduce the levels of microorganisms, resulting in higher meat quality and longer shelf life.

In addition to its powerful antimicrobial properties. Ozone does not leave residues and is a safe and economical disinfection solution. Furthermore, ozone treatment does not affect the taste, texture, or color of meat, making it an attractive alternative for the industry.

Reduce The Early Chick Mortality

Early chick mortality can be significantly reduced using ozonated water in various poultry applications. A wide range of processes uses ozonated water, including egg hatcheries, potable water in poultry houses, disinfection of the interior of poultry houses during period changes, production areas, chiller units, and process water disinfection.

Ozone has numerous benefits for the poultry industry, including improved chicken health and reduced need for vaccines and medications. Ozone gas is also used for disinfecting incubators, nest boxes, and production farms and is effective against pathogens like E. coli and Pseudomonas. Unlike formaldehyde, methanol, peracetic acid, and chlorine, ozone is a natural disinfectant that leaves no residue and poses no risk of chemical residues. By taking advantage of the power of ozone, the poultry industry increased shelf life and produced higher-quality, healthier products for consumers while also promoting animal welfare.

Enhancing Food Safety by Eliminating Foodborne Pathogens

The FDA has approved the use of ozone as a safe and effective food additive and antimicrobial agent in processing all foods, including poultry meat ensuring food safety. This ruling allows for using ozone as an alternative to traditional chemical antimicrobials, which can be hazardous and leave harmful residues. Additionally, ozone meets the growing consumer demand for safe and high-quality beef products. By using ozone in food processing, food manufacturers can ensure their products’ safety and quality while reducing costs and promoting sustainability. Ozone has been demonstrated to be effective against a wide range of foodborne pathogens, making it a valuable tool in the fight against foodborne illness.

Absolute Ozone Generators are the Best Choice for Ozone Meat Disinfection

For the past 25 years, Varius meat industries have successfully applied Absolute Ozone® technologies. Absolute Ozone® generators play a crucial role in preserving fresh meat by preventing microbial contamination and extending its shelf life. We have a highly experienced and knowledgeable engineering team that can assist you in the following areas:

- Selecting the Right Size Absolute Ozone® Ozone Generator for Your Ozone Meat Disinfection Application.

- Ensure you have the correct air preparation/feed gas to supply the oxygen concentrator or help choose the correct oxygen supply.

- Supply all necessary accessories, such as online monitoring and control equipment.

- Help with a complete initial design, installation guidance, and process details with maximum profitability.

- Provide full technical support from expert application engineers every step of the way, before installation and throughout the years.