KEY FEATURES:

- Ozone largely eliminates mycotoxins and pathogens in fruit and vegetable products.

- Ozone does not leave residues.

- Ozone saves money over a longer period of time than any other alternative.

- Ozone is Generally Recognized as Safe (GRAS) for use in food processing.

- lower bacterial levels

- Safe for the environment

- Improve water quality and reduce water usage

OZONE FOR FRUIT & VEGETABLE DISINFECTION

Throughout the different stages of production—harvesting, transportation, and storage—fresh fruits and vegetables are vulnerable to contamination by microorganisms and pathogens. Such contamination can lead to significant economic losses due to spoilage and reduced shelf life. Moreover, the presence of harmful pathogens, such as Escherichia coli or Listeria, poses a serious threat to public health and may result in further economic consequences, including recalls, legal liabilities, and a loss of consumer confidence.

Traditional disinfection methods typically involve rinsing produce with antimicrobial chlorine-based solutions. However, these treatments can leave behind harmful residues and by-products on the surface of fruits and vegetables, some of which are potentially carcinogenic and pose health risks to consumers. In addition, the use of chlorine or chlorine dioxide in wash water can be costly. Finally, the reliance on hazardous chemical disinfectants can have a detrimental impact on the environment, contributing to water pollution and ecological harm.

Fortunately, ozone treatment provides an excellent alternative for disinfecting fruits and vegetables. Unlike traditional chemical disinfectants, ozone leaves no harmful residues and is significantly more environmentally friendly. It also provides a cost-effective and highly efficient method for ensuring microbial safety, making it a preferred choice for many producers.

Ozone is widely used in the food industry to enhance food safety, preserve the quality of fresh produce, and extend shelf life.

A common question is whether ozone will work in a specific application. The answer is straightforward: wherever producers currently use toxic chemicals such as chlorine, hydrogen peroxide, or bromide for vegetable washing, ozone can serve as a safe and effective replacement.

Regulatory and safety issues

Various government agencies regulate the production, handling, and sale of fruits and vegetables to ensure their safety and quality. The regulatory and safety issues can include concerns around pesticide residues, microbial contamination, and foodborne illness outbreaks. Ensuring their safety and compliance with regulatory requirements is essential. Here are some regulatory and safety issues related to fruits and vegetables: The use of pesticides is regulated by government agencies such as the Environmental Protection Agency (EPA) in the United States, which sets limits on pesticide residues in foods. Additionally, the FDA has established regulations and guidelines to prevent microbial contamination, including the Food Safety Modernization Act (FSMA).

Additionally, safety considerations and potential risks associated with ozone exposure in vegetable purifiers are essential. Ozone exposure can aid in washing and decontaminating vegetables, influencing microbial inactivation and storage, thereby potentially extending shelf life and enhancing safety.

The Benefits of Ozone Treatment in the Fresh Produce Sector.

Ozone is listed as Generally Recognized As Safe (GRAS) by the U.S. Food and Drug Administration (FDA). This means that ozone is considered safe for use in food applications when applied in accordance with good manufacturing practices. The impact of ozone concentrations on the effectiveness of decontamination and microbial load reduction is significant, as higher concentrations can enhance the antimicrobial effects.

Ozone is an efficient, cost-effective, and ecologically friendly technique that does not leave a residue. Washing fresh fruit with ozonated water is the most effective way to disinfect and prevent cross-contamination, while also helping to remove pesticides, which reduces the amount of water required for washing and results in significant cost savings for producers. Several studies have demonstrated the efficacy and usefulness of ozone for disinfecting fruits and vegetables. Ozone acts as a powerful oxidant, breaking down contaminants and microorganisms on a molecular level.

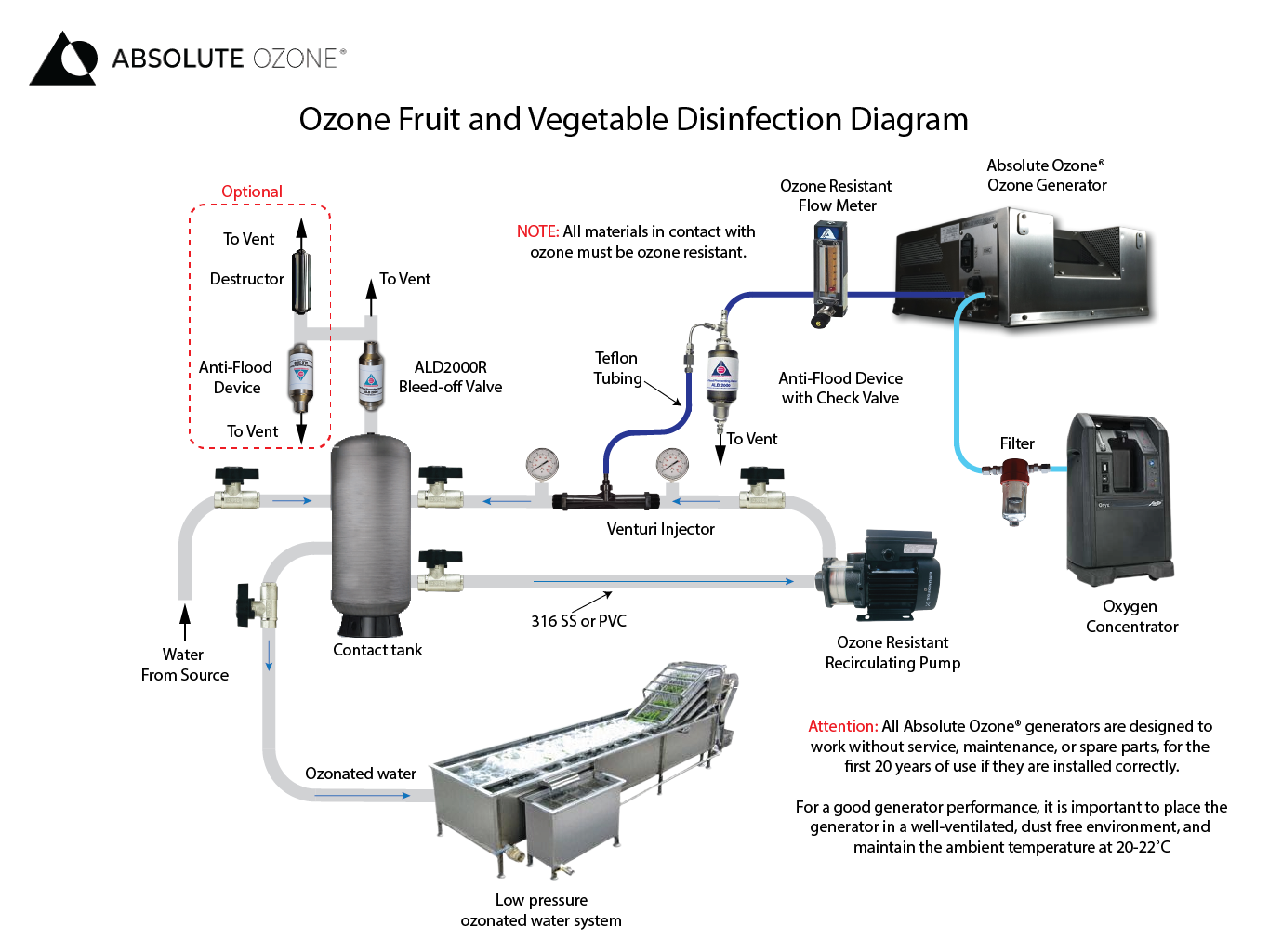

A simple system incorporating Absolute Ozone generators is a cost-effective, safe, and environmentally friendly method for producing ozonized wash water. By incorporating ozone treatment into their processes, producers can help improve food safety, reduce waste, improve mould and bacteriological kill, minimize product loss, and increase shelf life in the fresh produce sector.

OZONE: THE ALL-NATURAL SOLUTION

The versatility and effectiveness of ozone make it an ideal disinfectant for a wide range of applications. The formation and characteristics of ozone, including the presence of oxygen atoms, contribute to its powerful disinfecting properties. Here are some examples of the versatility of ozone:

- Fruit and vegetable disinfection: Ozonated water is a highly effective disinfectant that can be used to wash fruits and vegetables, eliminating harmful bacteria, viruses, and fungi. It can also help remove pesticides and other contaminants that contribute to spoilage. Using ozonated water to disinfect fresh produce can help extend its shelf life, reduce food waste, and enhance food safety.

- Produce storage: Ozonated water can also be used during storage and cold storage. By treating produce with ozonated water before storage, the growth of bacteria, fungi, and other microorganisms can be inhibited, thereby helping to prevent spoilage and extend the produce’s shelf life. Additionally, ozone gas can be used for reducing microbial growth during chilling storage and washing lettuce in stagnant water.

- Food processing: Ozonated water can be used in food processing to disinfect equipment and surfaces. It is an effective and safe disinfectant that can help improve food safety, reduce spoilage, and prevent cross-contamination.

- Irrigation: Ozonated water can effectively disinfect irrigation water, thereby reducing the risk of contamination from harmful bacteria, viruses, and fungi. This can help to maintain the health of crops and prevent foodborne illnesses.

- Packaging: Ozonated water can also be used to disinfect packaging materials, thereby reducing the risk of contamination during transportation and storage.

FACT ABOUT OZONE FOR FRUIT & VEGETABLE DISINFECTION

It is essential to recognize that the incorrect implementation of ozone technology is both wasteful and ineffective.

- Ozone is not a cleaning agent. It is essential to thoroughly wash vegetables to remove all dirt from their surfaces before ozone disinfection. Unremoved dirt will react with ozone, leaving almost no ozone available for disinfecting food or produce.

- Monitoring and controlling residual ozone is crucial to ensure adequate disinfection and minimize ozone waste.

- Spraying should be done at the lowest possible pressures or replaced with dipping in ozonated wash water.

-

Unfortunately, many ozone generators currently available on the market produce ozone at concentrations of 3% or less by weight. At such low concentrations, only about 20–30% of the ozone can be effectively dissolved in water, meaning up to 70% of the ozone—and therefore a significant portion of the investment—is wasted. In fact, low-efficiency systems can end up costing over USD 10,000 more than high-performance alternatives, while delivering much lower effectiveness. To avoid these inefficiencies and unnecessary expenses, it is essential to choose an ozone generator from a manufacturer that can guarantee both high ozone concentration and proven performance. This ensures the system delivers truly effective and economical ozone water treatment for your specific application.

OUR KNOWLEDGEABLE AND HIGHLY EXPERIENCED ENGINEERING TEAM WILL HELP YOU WITH THE FOLLOWING:

- Selecting the Right Size Absolute Ozone® Ozone Generator for Your Ozone Fruit and Vegetable Disinfection

- Supply the oxygen concentrator or help choose the correct oxygen supply by ensuring you have suitable air preparation and feed gas.

- Supply all necessary accessories, such as online monitoring and control equipment.

- Help with a complete initial design, installation guidance, and process details with maximum profitability.

- Provide full technical support from expert application engineers every step of the way, before installation and throughout the years.

Contact us now. Absolute Ozone will be happy to assist you with any questions you may have.