KEY FEATURES:

- Ozone eliminates mycotoxins and pathogens.

- Ozone gas does not leave residues.

- Ozone saves money over a longer period of time than any other alternative.

- Ozone is Generally Recognized as Safe (GRAS) for use in food processing.

- lower bacterial levels in cold storage rooms

- Safe for the environment

- Increase the products shelf life

Ozone for Cold Rooms

Food producers are continually seeking effective and economical methods to store food and extend the shelf life of their products. Cold rooms are one of the most common methods of preserving fruits, vegetables, meat, and fish. However, Cool storage is expensive and energy-intensive. In addition, it is not the most effective method. Refrigeration does not destroy microorganisms. Food remains susceptible to microbial growth, fungal decay, and pests during storage. The use of ozone gas for cold storage is an excellent alternative. It inactivates microorganisms in fresh products, including fruits, vegetables, meat, and other food items. Ozone is a highly effective and economical method for storing food and extending its shelf life.

Ozone treatment is the most effective, economical, and practical solution for food storage. An ozone system in cold rooms keeps the air germ-free and prevents the growth of mould and fungus. Several studies show that ozone is effective against numerous harmful food pathogens and extends the shelf life of food.

Advantages of Ozone in Cold Storage Rooms

Ozone systems in cold storage offer several benefits. Ozone is a powerful disinfectant with antimicrobial properties that can effectively inactivate bacterial spores, moulds, yeasts, protozoa, and viruses. By using ozone, cold room operators can reduce their reliance on chemical disinfectants, minimize waste, and save energy. The ozone system has enhanced food safety and extended the shelf life of various foods, including seafood, meats, fruits, and vegetables, during storage and processing. Another key advantage of ozone is that it leaves no residue and does not affect the taste, smell, or quality of stored food. Ozone systems are easily installed within existing cold storage air handling systems. With the Absolute Ozone system, the cost of the equipment can be quickly recovered because ozone helps minimize food waste and reduce the need for frequent restocking, which in turn saves money and lowers operating costs.

What is Ozone, and How Does it Work?

Ozone is a naturally occurring gas that can be artificially generated for use in various applications, including food safety and preservation in cold storage. It is a highly reactive gas that can eliminate odours, mould, bacteria, and other harmful microorganisms that can grow in cold rooms, posing a risk to food safety.

Ozone is generated by recombining oxygen molecules, creating ozone molecules that can then be released into the cold room. Once in the cold room, the ozone gas will react with any organic matter they encounter, such as bacteria, mould, or odours. Ozone molecules contain an extra oxygen atom, which can bond with organic matter and break it down into harmless byproducts, such as carbon dioxide and water.

Ozone can also be used to remove ethylene gas in cold rooms. Ethylene is a natural gas that is produced by fruits and vegetables during the ripening process. Ethylene gas can cause accelerated ripening and spoilage of nearby produce, affecting the taste, texture, and appearance of fruits and vegetables. Ozone is an effective method for removing ethylene gas in cold rooms. It oxidizes ethylene, breaking it down into carbon dioxide and water. By removing ethylene gas, ozone can help slow the ripening process and extend the shelf life of fruits and vegetables. It can also help maintain the quality and freshness of stored fruits and vegetables.

How to Use Ozone in Cold Rooms

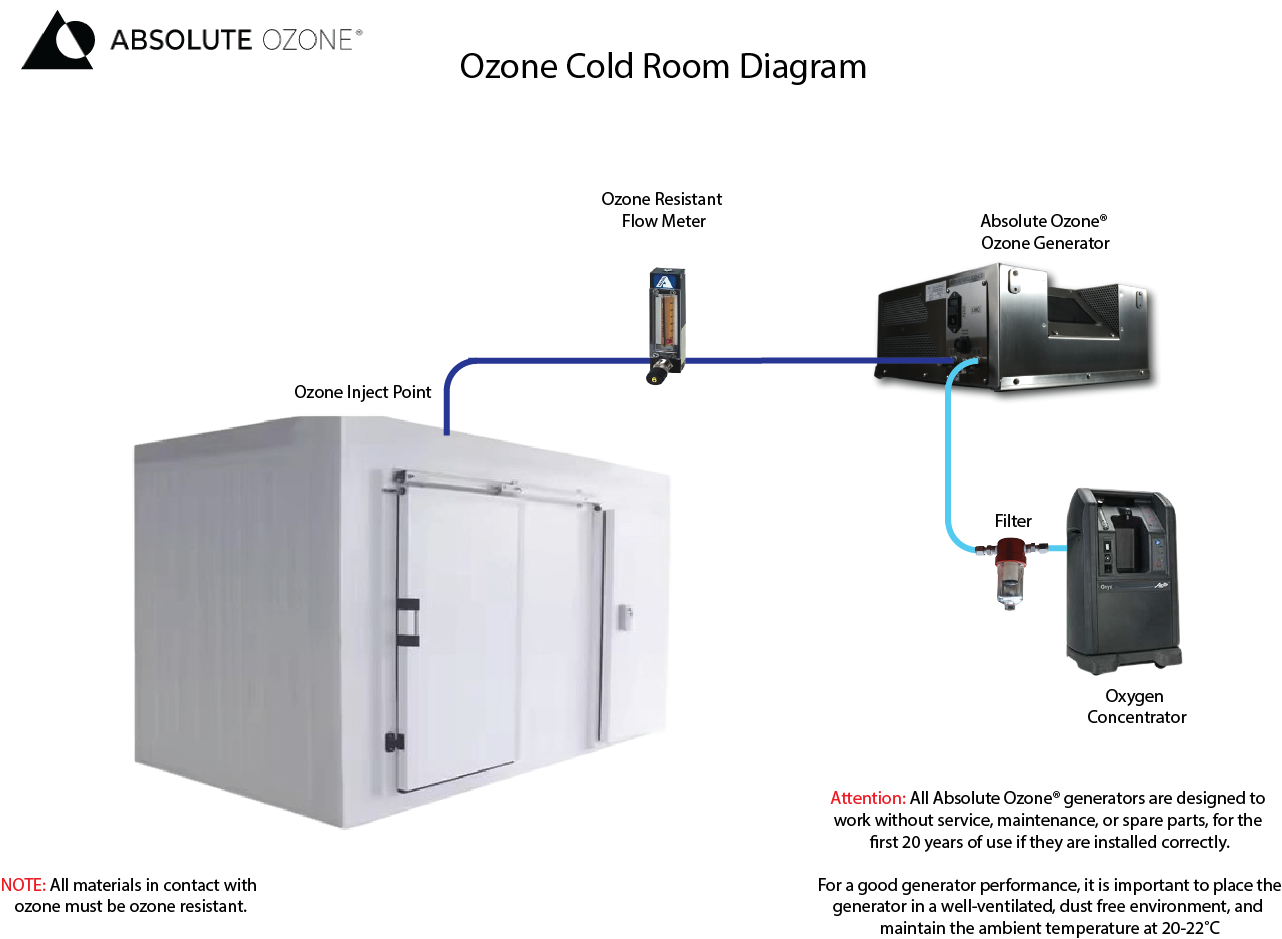

Here are some general steps on how to use ozone systems:

- Determine the appropriate ozone concentration: The concentration of ozone needed to be effective depends on the size of the cold room and the intended use; it generally ranges from 0.1 to 0.3 parts per million (ppm).

- Select the suitable ozone generator: Various types of ozone generators are available on the market, ranging from compact, portable units to large, industrial-sized models. Choose a generator appropriate for the cold room’s size and intended use.

- Let the ozone work: Allow the ozone to circulate in the cold room for the recommended time. The duration of the treatment will depend on the size of the cold room and the intended use.

- Ventilate the cold room: After the treatment is complete, ventilate the cold room to remove any residual ozone. Open all doors and windows and use fans to circulate fresh air throughout the space. Ensure the ozone concentration is safe before re-entering.

Ozone can enhance the storage and shelf life of various products in cold storage facilities. For example, ozone can sterilize meat and prevent the growth of harmful bacteria. It can also reduce losses due to deterioration and improve the tenderness and shelf life of the meat. In the case of fish, ozone can eliminate microorganisms in cold storage rooms, preventing food from putrefying and illness in consumers. It can also deodorize the fish, reduce ammonia emissions, stabilize the ph, and extend its shelf life. Ozone gas can control ethylene production for fruits and vegetables, delaying natural ripening and oxidizing it into an antimicrobial compound. It can also leave fruits and vegetables free of pathogens and chemical residues. In the egg industry, ozone helps prevent the growth of fungi, ensuring the preservation of the eggs’ initial flavour and quality. Lastly, in cheese conservation and maturation chambers, ozone can avoid the appearance of mould, reduce weight loss, and eliminate odours.

Absolute Ozone® will be happy to help you; we offer a unique 5-year warranty and unlimited assistance to ensure that the Ozone Generator is adequate for your storage room and product. Our knowledgeable team will help you with the following:

- Selecting the Right Size Absolute Ozone® Ozone Generator for Your Ozone Bottling Application

- Ensure you have the correct air preparation or feed gas to supply the oxygen concentrator, or help choose the correct oxygen supply.

- Supply all necessary accessories, such as online monitoring and control equipment.

- Help with a complete initial design, installation guidance, and process details with maximum profitability.

- Provide full technical support from expert application engineers every step of the way, before installation and throughout the years.

Contact us now, our staff will help you explore all the possibilities ozone can offer your cold storage facility.