KEY FEATURES:

- Ozone largely eliminates mycotoxins and pathogens in Dairy products.

- Ozone does not leave residues.

- Ozone saves money over a longer period of time than any other alternative.

- Ozone is Generally Recognized as Safe (GRAS) for use in food processing.

- lower bacterial levels

- Safe for the environment

- Eliminate the manure smell in the barn

- Improve water quality

OZONE FOR DAIRY

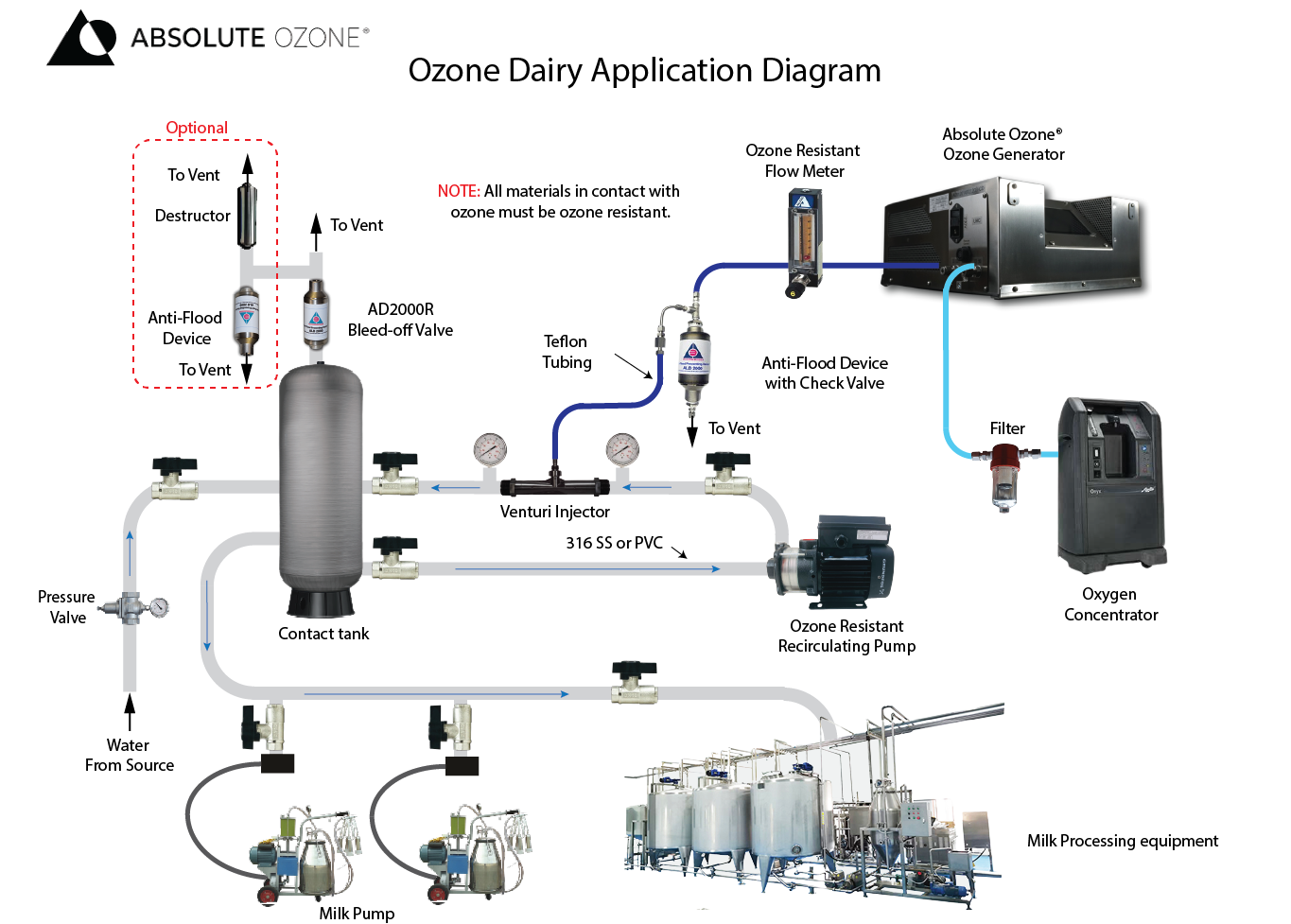

The use of ozone dairy has been shown to reduce the cost of sanitation and disinfection in many dairy processing applications such as Hoof Bath, Teat wash and disinfection, Drinking water treatment, Biofilms, surface disinfection, Clean in Place (CIP) system, etc.

OZONE FOR DAIRY DISINFECTION

Milk is an ideal culture medium for microorganisms. Also, bacteria in milk can adhere to stainless steel surfaces forming biofilms.

The presence of pathogenic microorganisms in biofilms is an important health hazard. Also, it is the primary cause of contamination. Moreover, Biofilms are hard to eliminate and they are formed in all the equipment that comes into contact with dairy. For that reason, industries need a large amount of hot water and chemicals.

Due to ozone’s high oxidation potential, it is very effective at killing bacteria on equipment surfaces (Ozone is superior to chlorides against biofilms). This technology offers an economical solution, safe because it does not require additional chemicals or the use of water to rinse chemical residues from the equipment after treatment.

OZONE FOR BOVINE DISEASES

Further, dairy farms must deal with cow disease. In fact, bovine mastitis is the most common and costly disease in the dairy industry. Besides, traditional antibiotic treatment has a low cure rate and leaves drug residues in the milk, generating significant economic losses for the industry.

Dairy farms have begun to use ozone to treat bovine mastitis. The use of ozone therapy for a short period of exposure is effective for spores and viruses. For example, studies have shown that Ozone treatments achieve 60% recovery in infected cows without the administration of antibiotics. Additionally, ozone is a safe method of treating common bovine diseases because it does not leave antibiotic residues in milk.

OZONE FOR ODOR CONTROL

Another application of ozone in the dairy industry is odor control. The presence of unpleasant odors in dairy processing facilities can negatively impact the working conditions for employees and adjacent areas. Ozone can effectively neutralize and eliminate odors by oxidizing and breaking down the compounds that cause them.

WHY ABSOLUTE OZONE?

For the past 25 years, the Dairy industry used the Absolute Ozone® technologies successfully in various dairy applications, such as equipment disinfection, bovine disease treatment, odor reduction, and many others.

Our engineering team can provide a lot of valuable support and expertise for businesses looking to incorporate ozone technology into their dairy applications. We will help you with:

- Selecting the Right Size Ozone Generator: We can help businesses determine the appropriate size of Absolute Ozone® Ozone Generator needed for their specific application.

- Oxygen Supply: This involves making sure the air preparation and feed gas are properly configured for optimal performance.

- Supplying Necessary Accessories: To ensure a fully functional ozone system, including online monitoring and control equipment.

- Initial Design and Installation Guidance: This is important to maximize profitability and efficiency.

- Technical Support: Once the ozone system is installed, We can provide ongoing technical support from expert application engineers to ensure optimal performance and to troubleshoot any issues that may arise.

Absolute Ozone® generators are the most efficient in the industry and are backed by a 5-year performance and quality guarantee.