Share This Story, Choose Your Platform!

Understanding Off-Gassing in Ozone in Water Systems

Ozone generators are widely used across various industries for water treatment, air purification, and sanitation due to their powerful oxidizing capabilities. While the benefits of ozone are undeniable, it’s crucial to understand the potential byproducts, particularly off-gases, that result from ozone applications, especially in systems where ozone is dissolved in water. Proper management of off-gases is essential for ensuring safety, efficiency, and compliance with environmental regulations.

What Are Off-Gases?

Off-gases are gases that are released as a byproduct of a process. In the context of ozone generators, off-gases refer to any excess ozone that is not dissolved or utilized in the water treatment process. This can include residual ozone and ozone gases released during ozone application.

Ozone used in water treatment systems is typically injected into the water to break down organic matter, eliminate pathogens, and remove contaminants. However, not all of the ozone gets dissolved in the water. The excess ozone that fails to dissolve or is not fully utilized is released into the atmosphere as off-gas.

Why Is Off-Gas Management Important?

- Health and Safety Concerns: Ozone is a powerful oxidant and, at high concentrations, can harm human health. If not adequately managed, exposure to off-gases containing residual ozone can cause respiratory irritation, headaches, and more severe health issues. Therefore, ensuring that off-gas is treated or safely vented is critical to protecting workers and the environment.Exposure to off-gassing can have a range of health effects, from mild to severe, depending on the level and duration of exposure.

- System Efficiency: If ozone is not effectively dissolved in water, the system is not operating at peak efficiency. Excess ozone in off-gas indicates that the system could be optimized to use the ozone produced better, improving overall performance and reducing operational costs.

Standard Methods for Managing Ozone Off-Gases

Destruction Units: Ozone destruction units are commonly used to neutralize excess ozone in off-gases before vaping into the atmosphere. These units typically use catalytic or thermal processes to break down ozone into oxygen, making the off-gas safe for release.

Degas Chambers: In water treatment systems, degas chambers separate undissolved ozone from the treated water. The ozone-rich off-gas is then sent to an ozone destruction unit, ensuring no harmful gases are released into the environment.

Ozone Sensors: Ozone sensors are often installed near the point where off-gases are vented to monitor ozone concentrations. If ozone levels are too high, alarms can trigger, and corrective action can be taken immediately.

Ozone in Water: Challenges and Opportunities

Using ozone in water treatment offers many benefits, such as effectively removing bacteria, viruses, and chemical contaminants. However, off-gassing remains challenging, especially in systems with lower solubility rates or improper injection techniques.

- Solubility Issues: Ozone is relatively low solubility in water, which makes it difficult to achieve high concentrations without producing excess off-gas. Optimizing the injection method, such as venturi injectors, can help increase solubility and reduce off-gas production.

- pH and Temperature Factors: The effectiveness of ozone in water is influenced by pH and temperature. Ozone is more soluble in cooler water, but in warmer water, such as in pools (30°C or higher), solubility decreases, potentially leading to more off-gassing. Managing these variables can help balance efficiency and safety.

Best Practices for Off-Gas Handling to Mitigate Health Risks

- Proper Ventilation: Ensure that ozone generators and water treatment systems are installed in well-ventilated areas to prevent the buildup of ozone concentrations in the air. This is particularly important in enclosed spaces where off-gas might accumulate.

- Ozone Leak Detection: Monitor for ozone leaks regularly and ensure that all connections, seals, and injectors in the system are secure. Adding an ozone leak troubleshooting section in system manuals can help operators address common issues quickly.

- Routine Maintenance: Keep ozone destruction units and degas chambers well-maintained to ensure they function efficiently. Any malfunction in these components can lead to dangerous levels of off-gas escaping into the atmosphere.

Conclusion

Managing off-gases in ozone generation and water treatment systems is essential for maintaining safety and efficiency. While ozone is an incredibly effective tool for disinfection and purification, proper off-gas management maximizes its benefits while minimizing risks to health and the environment. By implementing the right technology and best practices, industries can harness the power of ozone while staying compliant with safety and environmental standards.

When a customer buys a car all specifications like, horsepower, torque, mileage, top speed, and other features are available, so the customer could make an intelligent choice according to his requirements, needs, and desires. It is therefore surprising that when a customer buys an ozone generator system, he is treated like a person incapable of making an intelligent choice. As a result, he could be persuaded to purchase a system that does not meet his needs and requirements.

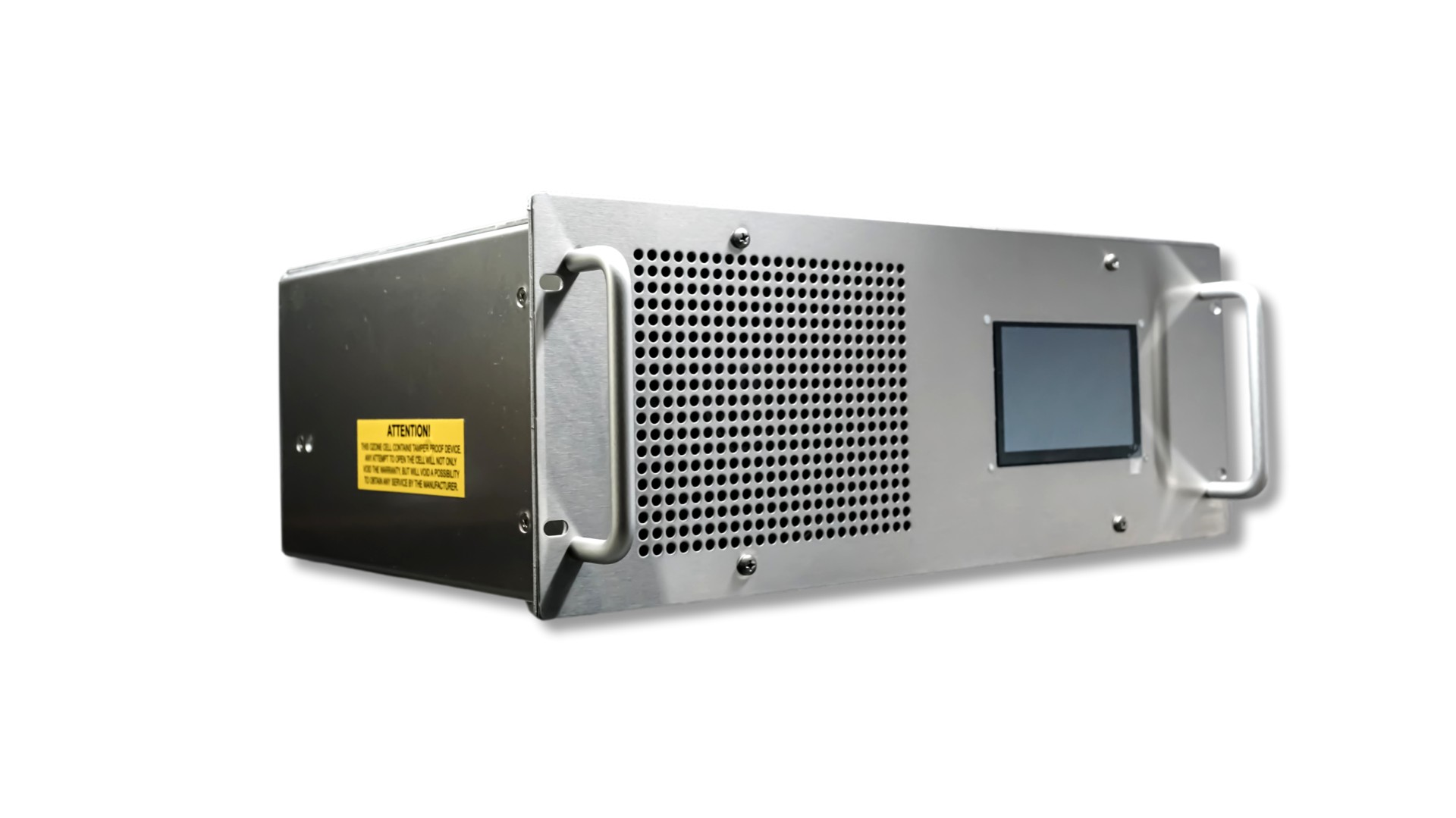

With the assistance of Absolute Ozone®, the system will work. Consequently, reducing the amount of wastewater and process water consumption. In addition, Ozone will significantly reduce costs. We at Absolute Ozone® provide the most advanced, efficient, and economical generators to all of our customers.

Contact us now, We will help you with your project