KEY FEATURES:

- Ozone kills bacteria instantaneously and is more effective than any other oxidant available!

- Ozone is not commonly linked with by-products and naturally reverts to oxygen after usage, it has no taste or odor.

- Ozone is generated on-site; therefore, no dangerous storage or handling is required.

- Ozone allows for lower operating costs, maintenance costs, and chemical costs.

OZONE FOR BOTTLED WATER

Ozone Bottling Water

For over 50 years, ozone has played a key role in the bottled water industry as an effective method of purification. Ozonation helps ensure that bottled water meets stringent microbiological standards by effectively eliminating microorganisms. In fact, one of the main challenges during the early days of the bottled water industry was the proliferation of microbial growth in the product. The introduction of ozone treatment systems successfully addressed this issue, establishing ozonation as a critical step in maintaining water quality and safety.

The Advantages of Ozone for a Safe and Efficient Bottled Water Industry

Ozone is widely used in the bottled water industry as a robust and reliable method of purification. It effectively eliminates bacteria, viruses, and other contaminants, ensuring water is safe for human consumption. As a result, ozonation is a critical step in the production process, helping to maintain product safety and extend shelf life by preventing microbial growth.

Today, some of the most critical contamination risks in bottling plants are associated with containers and the packaging line. Microorganisms, fungi, and even residues from cleaning agents can be present in these areas, leading to both chemical and biological contamination of the final product.

In recent years, concern over the presence of disinfection by-products—especially Trihalomethanes (THMs)—has grown significantly. THMs are classified as possible human carcinogens in Canada’s Drinking Water Guidelines, which set a maximum limit of 100 µg/L (micrograms per liter). Unlike chlorine-based treatments, ozone is generated on-site and breaks down into oxygen, leaving no harmful chemical residues or by-products behind. This makes ozone a safer alternative to chlorine, which can produce THMs and other undesirable compounds.

Ozone’s versatility adds even more value to the bottling industry. It can be used to disinfect water, bottle caps, bottles, and the filling equipment itself. It helps eliminate bacterial contamination during production and handling, ensures sterile storage conditions, and removes odors while improving taste. Additionally, ozone can oxidize and reduce THMs in the treated water and eliminate the need for high-temperature rinses, contributing to energy savings and process efficiency.

Efficient and Effective Ozone Treatment Disinfection:

Ozone (O₃) is a powerful and fast-acting disinfectant widely used in the bottled water industry. Composed of three oxygen atoms, ozone is highly reactive, making it extremely effective at eliminating bacteria, viruses, and other contaminants from water. Its ability to purify large volumes of water in a short time makes it an ideal solution for high-throughput bottled water production.

Improved Taste and Odor

Beyond disinfection, ozone also enhances the sensory quality of water by removing unpleasant tastes and odors. This results in a cleaner, fresher taste that improves the overall drinking experience. In sparkling water production, ozone treatment can be used alongside carbon dioxide infusion to maintain a crisp and pleasant flavor.

Extended Shelf Life

By inhibiting the growth of microorganisms, ozone treatment helps extend the shelf life of bottled water. When used with purified water, ozone ensures that the product remains safe and stable over time, offering consumers fresh, high-quality drinking water whenever needed.

Cost-effective and Environmentally Friendly

Ozone is a cost-effective and sustainable water treatment method. It requires no added chemicals and has low operating costs. Often used in combination with reverse osmosis and other purification technologies, ozone enhances water quality while minimizing environmental impact. Because ozone is generated on-site and naturally decomposes into oxygen, it leaves no harmful residues—making it a clean and eco-friendly solution for the industry.

The Ozonation Process

Understanding How Ozone is Applied in Water Bottling

The ozonation process is a cornerstone of the bottled water industry, ensuring that the water you drink is both safe and of the highest quality. Ozone gas, a powerful disinfectant, is introduced into the water through a method known as ozonation. This involves dissolving ozone into the water to effectively eliminate bacteria, viruses, and other harmful contaminants. The key to this process is maintaining a precise ozone concentration, which ensures thorough disinfection without leaving any harmful residues behind.

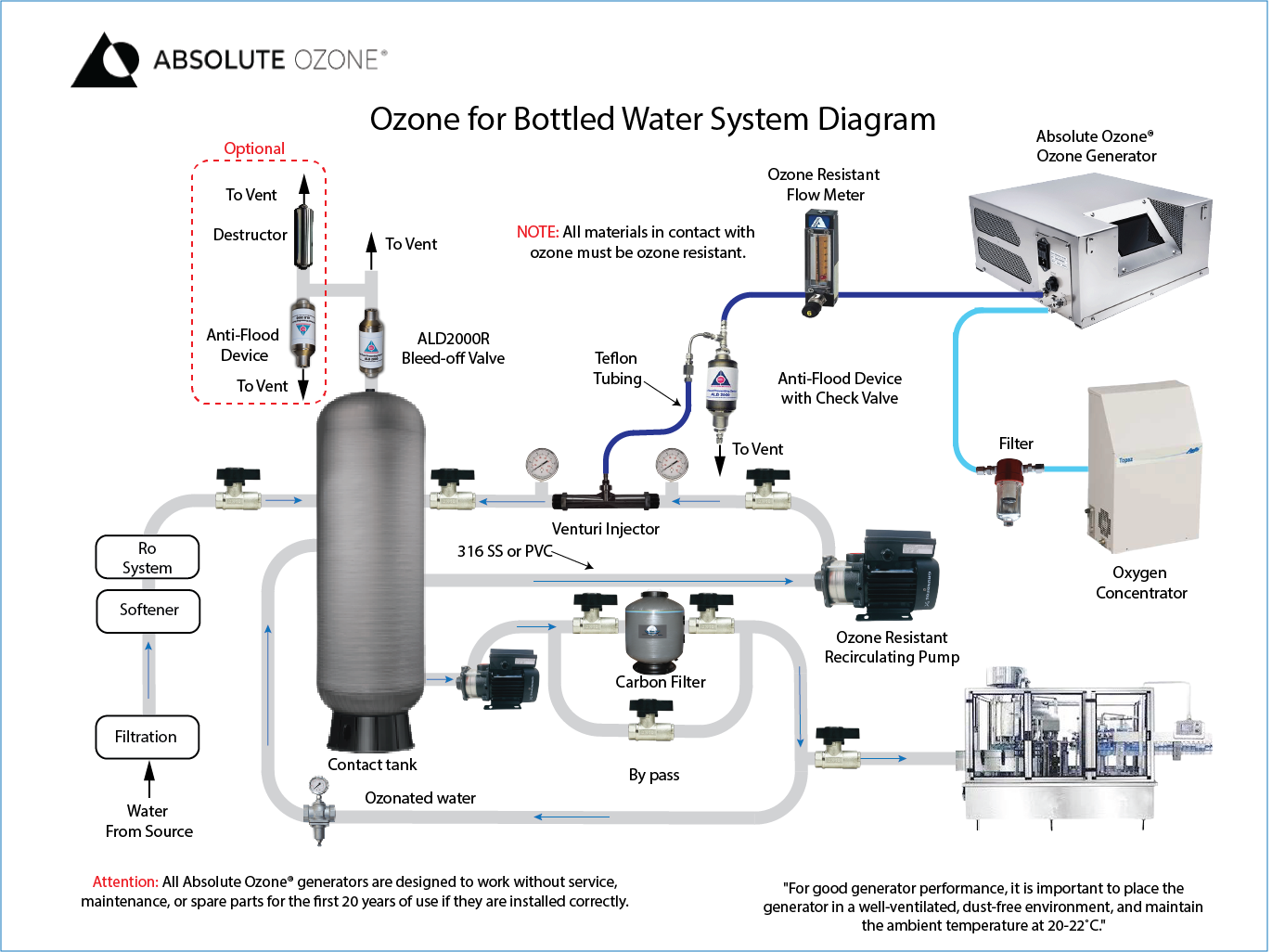

In water bottling plants, ozonation typically occurs just before the bottling stage. An ozone generator produces ozone gas, which is then injected into the water using a venturi injector or a similar contacting method. The ozone concentration is meticulously monitored to ensure it meets the required levels for effective disinfection. This step acts as an additional barrier against contamination, providing an extra layer of safety.

The ozonation process is designed to deliver a high level of disinfection while minimizing the risk of recontamination. Its effectiveness in eliminating microorganisms and extending the shelf life of bottled water has made it an increasingly popular choice in the bottled water industry. By incorporating ozonation, water bottling plants can ensure that their products are safe, clean, and enjoyable for consumers.

Ozone Generator Solutions for the Bottled Water Industry

Exploring Equipment and Technology Options

Ozone generator systems are essential in the bottled water industry, providing a reliable and efficient method for producing ozone gas used in water disinfection. Depending on the specific needs of the operation, producers can choose between different types of generators—primarily air-fed and oxygen-fed units—each with distinct advantages and considerations.

When selecting an ozone generator for bottled water production, key factors include the required ozone concentration, water flow rate, and the maintenance profile of the equipment. A properly engineered generator should deliver consistent ozone output to ensure effective disinfection and full compliance with industry safety and quality standards.

In addition to the generator itself, several supporting technologies are critical to a successful ozonation system. These include ozone concentration sensors, venturi injectors for efficient gas-liquid mixing, and recirculation pumps to enhance contact time. Together, these components help maintain the correct ozone dosage and ensure uniform and thorough water treatment.

By selecting the appropriate ozone system and integrating it with the right auxiliary equipment, bottled water producers can achieve superior water quality, reduce operational risks, and improve the overall efficiency and reliability of their treatment processes.

Ozone Treatment and Food Safety

Ensuring Compliance with Safety Standards and Regulations

Ozone treatment plays a critical role in food safety within the bottled water industry, ensuring that the final product is both safe for consumption and of the highest quality. Its use is regulated by strict standards set by agencies such as the U.S. Food and Drug Administration (FDA) and the Environmental Protection Agency (EPA).

To remain in compliance with these regulations, bottled water producers must implement well-defined ozonation protocols that ensure effective disinfection. Key parameters such as ozone concentration, contact time, water flow rate, and equipment performance must be consistently monitored and maintained. These measures are essential for delivering a safe product and meeting legal requirements. For example, the EPA’s National Primary Drinking Water Regulations include guidelines on disinfection practices, and ozone is listed as an approved disinfectant.

Ozone is a powerful oxidizing agent capable of inactivating a wide range of microorganisms, including bacteria, viruses, and fungi. Its broad-spectrum efficacy makes it an essential barrier against microbiological contamination, helping producers prevent potential health hazards.

Beyond compliance, ozone treatment contributes to product consistency and consumer trust. By prioritizing effective ozone integration and adhering to regulatory standards, bottled water companies can ensure public safety, meet consumer expectations, and strengthen their reputation for delivering clean, high-quality drinking water.

WHY ABSOLUTE OZONE®

We are one of the few manufacturers in the industry that guarantees the performance of our ozone generator. In addition, we eliminate any possibility of performance overstatement, which is sadly becoming more and more common in the ozone industry. Above all, we design to guarantee greater productivity. Our equipment requires practically no maintenance or spare parts.

Our goal is to provide an efficient and 100% reliable ozone generation system for your bottled water application and to provide customer service and support unmatched by our competitors.

With the Absolute Ozone® ozone generator, you can reduce your use of chemical products, lower costs, and achieve a successful return on investment for your company while improving your bottled water production.

Our higher ozone concentration and the unique design of the treatment system have excelled in beverage applications. As a result, several significant brands trust Absolute Ozone® generators to provide pure ozone for bottling applications as they seek efficiency and reliability.

OUR KNOWLEDGEABLE AND HIGHLY EXPERIENCED ENGINEERING TEAM WILL HELP YOU WITH:

- Selecting the Right Size Absolute Ozone® Ozone Generator for Your Ozone Bottling Application

- Supply the oxygen concentrator or help choose the correct oxygen supply by ensuring you have the proper air preparation/feed gas.

- Supply all necessary accessories, such as online monitoring and control equipment.

- Help with a complete initial design, installation guidance, and process details with maximum profitability.

- Provide full technical support from expert application engineers every step of the way, before installation and throughout the years.

Contact us now. Our staff will help you explore all the possibilities ozone can offer your project.