KEY FEATURES:

- Money savings due to lower operating costs over time

- No on-site chemical inventory

- No toxicant discharge, chloramines

- Water conservation due to no TDS buildup from disinfectants

- Ozone is produced on-site and requires no storage of dangerous chemicals

- Lower corrosion rates of the system

- No regular disinfection system maintenance required

- No special training for employees operating the system

- Elimination of Legionella spread and hazard to human health

- Eligibility for LEED certification

OZONE FOR COOLING TOWERS

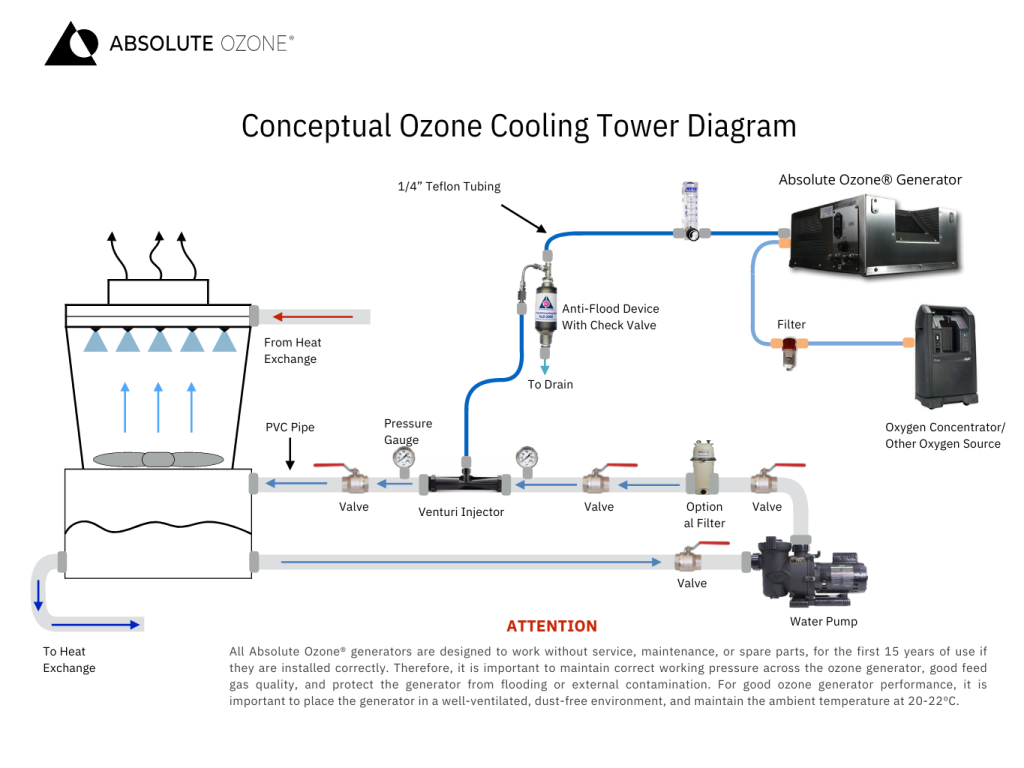

Cooling water systems are vulnerable to several challenges, including scaling, corrosion, and biofouling. Pathogenic bacteria, such as Legionella pneumophila, can exacerbate these problems by serving as nucleation sites for deposits or contributing to biofilm formation. Traditionally, chemical inhibitors and biocides have been used to control these issues; however, they pose risks related to storage, handling, and environmental impact. In recent years, ozone has emerged as a powerful and sustainable alternative for cooling tower water treatment. It is a highly effective biocide that decomposes rapidly, leaving no harmful residues and offering additional benefits such as water conservation and reduced chemical dependency.

Using Ozone in cooling water system:

Using Ozone in Cooling Water Systems

Thanks to improvements in ozone generator technology and reduced operational costs, ozone has become a popular alternative to conventional chemical treatment. Not only is ozone a highly efficient disinfectant, but its rapid decomposition also ensures minimal toxicity and environmental impact. Moreover, its application can support water reuse initiatives by maintaining clean and stable water quality.

According to multiple studies, maintaining an ozone concentration of at least 0.1 ppm in cooling tower water is effective for microbial control. Selecting the appropriate ozone generator depends on the total water volume and operational conditions.

For example, in a small 10 m³ cooling tower, only 1 gram of ozone needs to be dissolved in the sump water. However, considering ozone’s short half-life at ~35 °C (~8 minutes), continuous dosing is necessary. To maintain 1 g dissolved ozone, about 11 g/h should be injected, which requires a generator rated at approximately 15 g/h.

The Absolute Ozone® NANO 15 generator is ideal for this application, offering reliable ozone production and performance. It also provides a safety margin to accommodate seasonal increases in organic load or dust.

It’s important to consider not just ozone output, but gas concentration. The higher the ozone concentration in the gas phase, the greater the mass transfer into water, resulting in better disinfection performance. Absolute Ozone® offers air-cooled ozone generators with industry-leading gas concentrations, ensuring effective and consistent results.

Benefits of Ozone Application for Cooling Tower Water

-

Safe and User-Friendly: Ozone systems are easy to operate and inherently safe when properly designed, eliminating risks associated with handling hazardous chemicals.

-

Low Maintenance: Ozone systems require minimal maintenance compared to chemical treatment programs, making them a cost-effective solution over time.

-

On-Site Generation: Ozone is generated on demand at the point of use, eliminating the need for chemical storage, transport, or inventory management.

-

No Supplemental Disinfectants Needed: Due to its strong oxidizing power, ozone alone is sufficient for microbial control in most applications.

-

No Microbial Resistance: Unlike traditional biocides, microorganisms do not develop resistance to ozone, even with long-term use.

-

Highly Effective Disinfection: Maintaining a residual ozone concentration of just 0.1–0.2 ppm is enough to keep cooling towers and associated piping clean and free from biofouling.

-

Biofilm Elimination: Ozone effectively removes biofilms, thereby enhancing heat exchanger efficiency and reducing the need for fouling-related maintenance.

-

Control of Legionella: By eliminating biofilms that harbour Legionella pneumophila, ozone significantly reduces the risk of Legionnaires’ disease.

-

Low Corrosivity: Unlike chlorinated treatments, ozone does not contribute to corrosion when appropriately applied, thereby preserving the longevity of system components.

-

Environmentally Friendly: Ozone decomposes into oxygen, leaving no harmful or persistent residues in the system bleed or blowdown.

-

Chemical-Free Operation: In many cases, ozone can replace traditional biocides, dispersants, and corrosion inhibitors, lowering both operational complexity and chemical costs.

-

Effective Across a Wide pH Range: Ozone maintains its efficacy over a broad pH range, providing stable performance regardless of water chemistry variations.

-

Control of Mussel and Algae Growth: Ozone inhibits the growth of invasive organisms, such as mussels and algae, thereby supporting system cleanliness and enhancing flow efficiency.

Ozone treatment in cooling towers has been shown to enhance the performance of heat exchangers by preventing biological deposits more effectively than conventional chemical programs. Field data indicate efficiency improvements of up to 20% in chilled water systems, depending on system design and fouling conditions.

From an environmental perspective, the reduction or complete elimination of chlorine-based chemicals in discharge water aligns with sustainable water management goals. Ozone also disrupts biofilms, which typically serve as a matrix for scale formation. This results in improved heat transfer efficiency, lower chiller head pressure, reduced energy consumption, and extended equipment lifespan.

What Are Biofilms?

Biofilms are structured communities of microorganisms embedded in a protective matrix that adhere to wetted surfaces. These films shield pathogens from disinfectants that would otherwise inactivate free-floating organisms. Ozone effectively penetrates and destroys biofilms, improving both water safety and operational hygiene.

Contact us now if you need more information about your cooling tower system.