KEY FEATURES:

- Ozone virtually eliminated fish mortality and disease saving thousands of dollars for fish farms,

- Increased fish weight gain in the same period of time (about 40% in our client experience) increasing fish farm profits

- Ozone completely eliminated the “swampy” taste

- Ozone has been certified as organic and has been approved by the FDA and USDA as a food contact substance.

OZONE FOR FISH FARMING & AQUACULTURE

The use of ozone in fish farming and aquaculture is revolutionizing the industry. After implementing Absolute Ozone® systems, farm operators consistently report higher customer satisfaction, better fish quality, and increased profitability. Many of them return to expand their systems across additional ponds—not only for the economic benefits, but also due to the enhanced taste, size, and health of the fish they produce.

Key Applications of Ozone in Aquaculture:

- Removal of Fine and Colloidal Solids:

Fine (1–30 microns) and colloidal (0.001–1 micron) particles remain suspended in water, bypassing conventional filtration. These solids reduce biofilter efficiency and cause fish stress. Ozone causes these particles to flocculate, making them removable via foam fractionation, filtration, or sedimentation—greatly improving water clarity and quality.

- Removal of Dissolved Organic Compounds (DOC)

DOCs give water a yellow-brown tint and are difficult to biodegrade. They accumulate with feeding and poor water exchange, leading to fish stress and biofilter inefficiency. Ozone oxidizes DOCs into simpler, more bioavailable compounds, enhancing nitrification and reducing waste buildup.

- Nitrite Removal and Biofiltration Enhancement

High production loads increase nitrite due to imbalanced bacterial activity. Nitrite levels as low as 2.8 ppm can slow fingerling growth by 5%. Ozone helps by oxidizing nitrite to nitrate and reducing organic load, supporting more efficient and balanced biofiltration.

- Disinfection

Ozone effectively inactivates bacteria, viruses, fungi, and protozoa, reducing pathogen loads from source and effluent waters.

Clients report:

- Up to 40% faster fish growth

- Drastic reduction in mortality and disease

- Better taste and appearance (e.g., one farm successfully rebranded Tilapia as “Northern Perch” after improving quality with ozone)

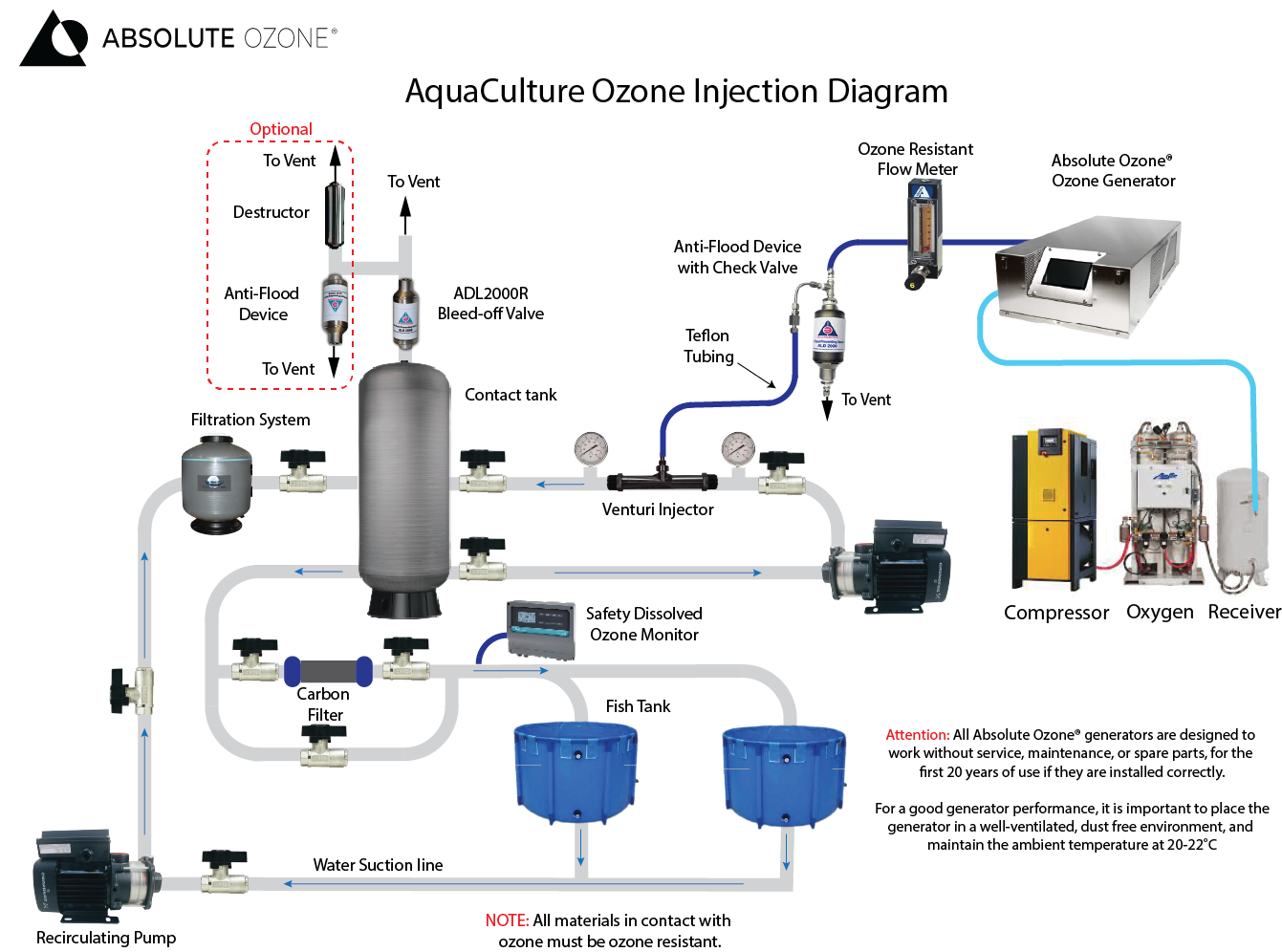

How an Ozone RAS (Recirculating Aquaculture System) Works

In a modern aquaculture setup, water must be continuously treated to ensure optimal health and growth. A complete ozone RAS system includes:

- Fish Tanks: Where aquatic species are raised.

- Mechanical & Biofiltration: Removes solid waste and converts ammonia to nitrate.

- Ozone Injection via Venturi: Oxidizes organic waste, nitrite, and pathogens in a contact tank.

- Oxygenation & Recirculation: Water returns clean, safe, and oxygen-rich to the tanks.

Ozone decomposes into pure oxygen, leaving no toxic residue, making it the most sustainable solution for aquaculture disinfection and water quality control.

Why Choose Absolute Ozone®?

- Proven success: Our clients report quick returns on investment.

- Highest efficiency: Industry-leading ozone generation technology.

- Full support: Unlimited free technical assistance from design to commissioning.

- Custom solutions: Proper generator sizing and system integration to meet specific needs.

Contact Us Today

Start improving your aquaculture operation with Absolute Ozone®. Whether you’re starting fresh or upgrading your existing system, we’re ready to support your project from concept to completion. Please click here to contact us. Let our expert team help you boost production, improve quality, and reduce costs.