KEY FEATURES:

- Moves easily through the soil

- Produced on-site. So, there is no need for hazardous chemical transportation or storage

- Most powerful oxidizer available. besides, is a green alternative

- Complex organics break down to carbon dioxide or less toxic molecules. Otherwise, the consequences could be more serious than the original contaminant to the ecosystem.

- Breaks down to oxygen. Consequently, these increased DO levels

OZONE SOIL REMEDIATION

Ozone soil remediation is a technique used to clean up soil contamination caused by various pollutants, including petroleum hydrocarbons, solvents, and pesticides. It involves injecting ozone gas into the soil, which oxidizes and breaks down the contaminants. Ozone is a powerful oxidant and can quickly degrade the contaminants into less harmful substances. Ozone soil remediation is considered to be a cost-effective and environmentally friendly solution compared to other soil remediation techniques, and it has been used successfully in many contaminated sites around the world.

WHY USE OZONE FOR REMEDIATION?

Recently, ozone has been used to clean up sites containing a variety of soil contaminants. It targets both biodegradable compounds that degrade slowly over time and non-biodegradable ones. If dissolved, many hydrocarbon compounds can be biodegraded, but when attached to soil particles, these contaminants are not readily degraded. Furthermore, the network of water pipes and utility lines through a site makes it not feasible to excavate, Ozone is easy to implement and does not require large soil movement. In fact, Ozone Soil Remediation shows a reduction of contaminants of 99%, which is quite remarkable.

CONTAMINANTS DESTROYED BY OZONE

Some of the contaminants that can be treated with ozone soil remediation include:

- Petroleum hydrocarbons

- Solvents such as MTBE and TCE

- BTEX (benzene, toluene, ethylbenzene and xylene)

- Pesticides

- PCBs

- Chlorinated solvents

- VOC’s

KEY OZONE REMEDIATION BENEFITS

- In addition to having low capital equipment costs, ozone implementation has low operating costs as well.

- The installation will also cause minimal disruption to the site.

- Ozone offers In-situ destruction of targeted components

- The rapid decrease of contaminant mass and concentration in soil and water. In fact, impressive results may be seen in weeks

- Clean reaction. Also, no hazardous by-product formation

- Microbubbles work to remove VOCs from soil pores and groundwater, which lowers the oxidative demand on soil that is typical of liquid oxidants.

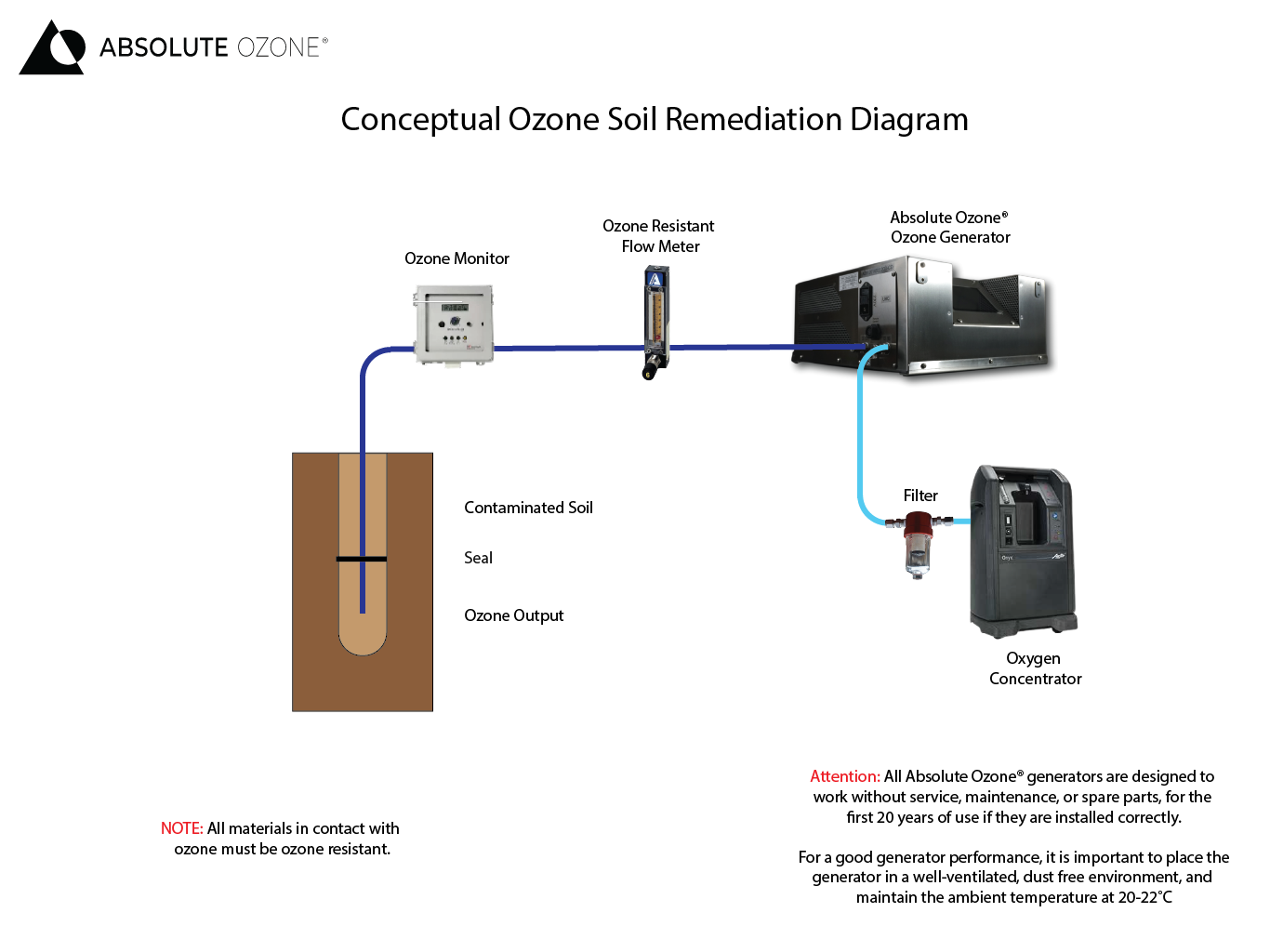

OZONE SOIL REMEDIATION PROCESS:

- Site Assessment: A thorough site assessment is conducted to identify the types of contaminants present in the soil and their concentration levels. The data collected from the assessment is used to determine the ozone injection rate and duration required for the soil remediation process.

- Soil Preparation: The soil is prepared for ozone injection by drilling boreholes or injecting pipes into the soil. Ozone is then injected into the soil through these holes or pipes.

- Ozone Injection: Ozone gas is injected into the soil using specialized equipment that pumps ozone gas into the soil at high pressure. The ozone gas oxidizes the contaminants and breaks them down into less harmful substances.

Once the ozone injection is completed, post-treatment validation is conducted to ensure that the contaminants have been successfully remediated to acceptable levels.

Absolute Ozone® will be happy to help you, We offer a unique 5-year performance warranty and provide unlimited assistance to assure that our client’s cold storage facility is effective. Our knowledgeable team will help you with:

- Selecting the Right Size Absolute Ozone® Ozone Generator for Your Ozone Bottling Application

- Supply the oxygen concentrator or help choose the correct oxygen supply by ensuring you have the correct air preparation/feed gas.

- Supply all necessary accessories such as online monitoring and control equipment.

- Help with a complete initial design, installation guidance, and process details with maximum profitability.

- Provide full technical support from expert application engineers every step of the way, before installation and throughout the years.

Contact us now, To Get Free Technical Support for your Ozone Soil Remediation Applications