Share This Story, Choose Your Platform!

Why Using Regular Air as Feed Gas in Ozone Generators is Not the Best Choice

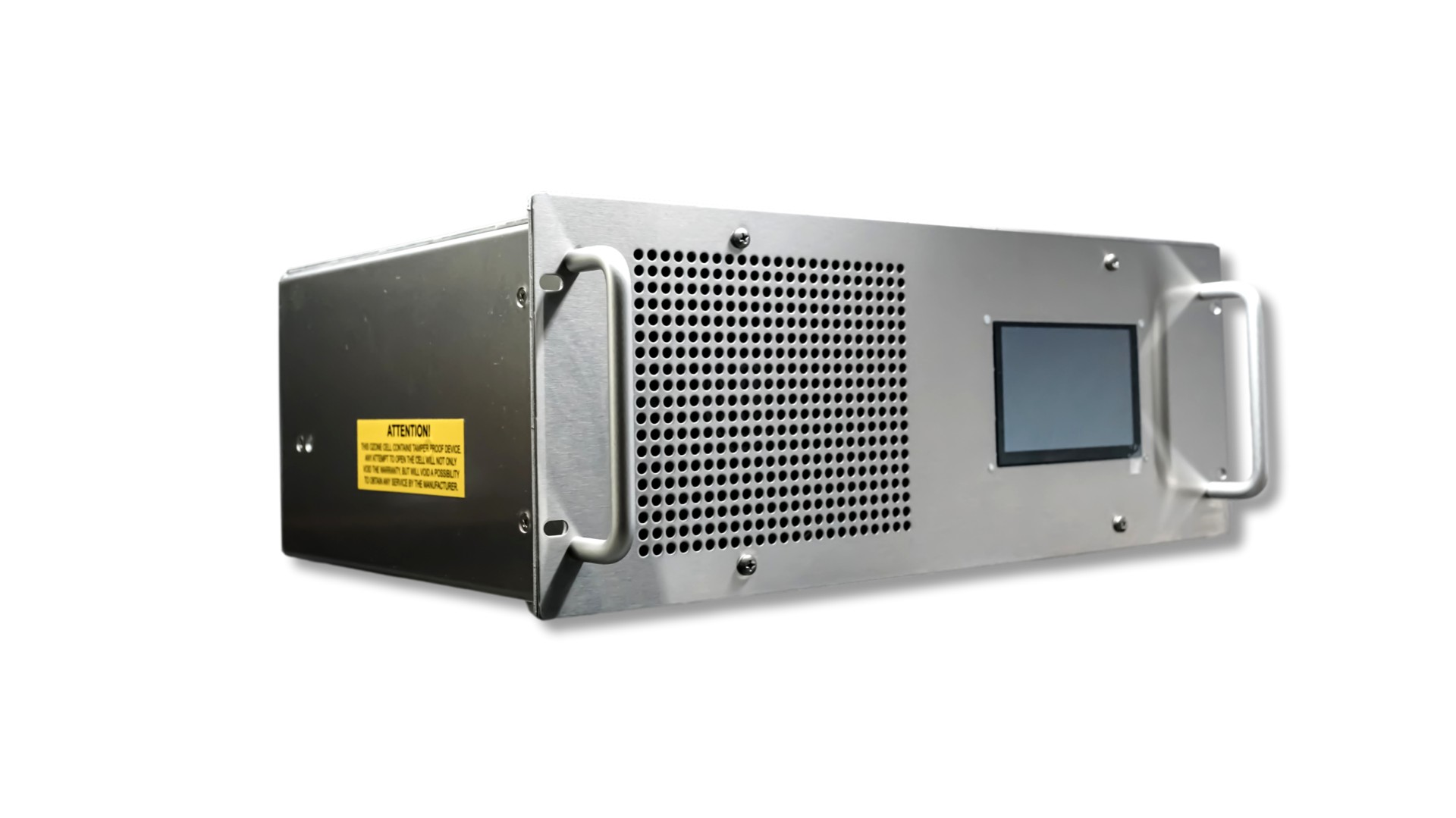

At Absolute Ozone, we often receive inquiries about operating ozone generators with regular air as feed, only to find that its ozone generation system is falling short of expectations. Why? The decision to use regular air instead of highly concentrated oxygen seemed economical at first, but it’s causing unexpected and costly setbacks. In the world of ozone generation, the choice of feed gas can make or break efficiency. Let’s delve into the intricacies and challenges of this seemingly simple decision and discover why the air we breathe might not be the best choice for optimal ozone production.”

Using regular air as a feed gas in ozone generators may seem like a smart decision initially, but it has several significant drawbacks that affect performance, efficiency, and cost in the long run.

1. Electrode Sedimentation and Ozone Production Decline

One significant challenge stems from the presence of nitrogen content in regular air, particularly Nitric Oxide. This compound tends to create sediment-like coatings on the ozone cell electrodes, hindering the smooth production of ozone. As a consequence, the efficiency of ozone production experiences a gradual decline. Over time, these sedimentations necessitate frequent cleaning and replacement of the electrodes, introducing a labour-intensive and costly aspect to the maintenance process. Addressing this issue becomes imperative to maintain optimal ozone generation performance and prevent disruptions caused by accumulating these coatings on the electrodes.

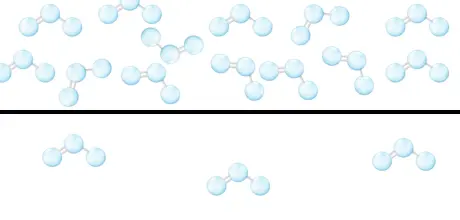

2. Ozone Concentration Drop and Reduced Dissolution Efficiency

The ozone concentration typically drops significantly when using dry air as the feed gas. This drop can be up to 5-7 times in smaller ozone generators, making it nearly impossible to dissolve more than 10% of the total produced ozone in water. Consequently, the actual ozone production diminishes substantially due to the lower oxygen content in the air. For instance, a system having 10 g/h of ozone might only dissolve 0.3-0.5 g/h when using dry air. This substantial reduction in efficiency renders the use of dry air impractical.

O3 Concentration %wt |

Percentage of O3 dissolved in water |

|

1% wt |

10% |

|

3% wt |

20-30% |

|

5-7% wt |

50-70% |

|

8-10% wt |

80-90 |

|

10-14% wt |

95% |

|

14-22% wt |

97% |

3. Impact on Treatment Processes

Moreover, low ozone concentrations generated from regular air can significantly slow reaction times when treating solids or gases. This inefficiency makes the treatment process wasteful, time-consuming, and ultimately costly. Additionally, high-concentration ozone generators like our NANO unit cease ozone production when the concentration drops below 60%, rendering them ineffective with dry air.

4. Cost Considerations

Contrary to potential assumptions, the cost of an oxygen concentrator is comparable to that of an air dryer. Therefore, the perceived cost-saving advantage of using dry air is outweighed by the numerous issues it introduces. From decreased efficiency to increased maintenance costs and ineffective treatments, the financial benefits don’t add up. Air contains only 21% oxygen. It takes more air volume to produce the same ozone quantity as oxygen. As a result, ozone concentration is low. For industrial applications that demand large quantities of ozone, such as water treatment and processing, it is best to produce ozone with oxygen because the total costs of ozone generation will be much lower.

In conclusion, while using regular air as a feed gas in ozone generators might seem plausible, the practical implications suggest otherwise. Getting an oxygen concentrator doesn’t cost more than an air dryer. So, the idea that using regular air saves money turns out to be not as true as it sounds. It’s like buying a cheap tool that seems like a good deal at first but ends up costing you more in the long run.

Choosing regular air brings more problems than savings. The efficiency drops, maintenance costs go up, and the treatment processes don’t work as well. It’s like buying a tool that constantly breaks and doesn’t do the job properly. So, even though using regular air might seem cheaper initially, the problems that come with it end up making it more expensive over time.

Investing in an oxygen concentrator is like choosing a reliable tool that lasts longer and works better. It might seem like a bit more money upfront, but in the long term, it’s a smarter choice because it keeps everything running smoothly, saving you from unexpected costs and making sure you get the most value out of your ozone generator.

The drawbacks, including reduced ozone production efficiency, electrode sedimentation, slower reaction times, and increased operational costs, make it a less intelligent choice than highly concentrated oxygen.

At Absolute Ozone, we prioritize efficient and sustainable solutions for ozone generation, ensuring optimal performance and cost-effectiveness for our clients.