KEY FEATURES:

- Ozone largely eliminates mycotoxins and pathogens in grain products.

- Ozone does not leave residues.

- Ozone saves money over a longer period of time than any other alternative.

- Ozone is Generally Recognized as Safe (GRAS) for use in food processing.

- Ozone treatment enhances the shelf-life of grain products.

- Ozone treatment modifies starch and protein properties.

OZONE GRAIN & FEED DISINFECTION

READ HOW OZONE FOR GRAIN & FEED DISINFECTION CAN SAVE LOSSES DURING THE STORAGE OF GRAINS!

Experts estimate that between 5 and 15% of the world’s production of cereal grains can be lost during the storage stage, and in some developing countries, this number can reach even 50%. Canada estimated the value of food waste at $31 billion per year. Insects, especially fungi and weevils, cause great losses in stored grains. Grains such as wheat grains are particularly susceptible to stored-grain insects, fungi, and bacteria contamination. By utilizing improved technology in grain storage, it’s possible to drastically reduce these losses. Currently, there are not many effective fumigants, partly because insects have become resistant to the active ingredients. Moreover, authorities have banned certain disinfectants for food processing due to their potential health and environmental risks. Furthermore, some species (such as grain weevils) develop inside grain kernels, which provide them with protection from chemical fumigants.

Effective grain storage management is essential to prevent fungal and mold infestations that thrive in humid and sultry environments, causing huge losses in material and quality, including the risk of mycotoxin contamination. These infestations can affect the price, feed quality, food product quality, and susceptibility to pest contamination in the grain trade. Furthermore, external microbiological contamination during wheat flour production and storage is a common issue, with contamination by E.coli and Salmonella sp. being prevalent. To maintain high-quality grain, several factors must be carefully monitored, such as temperature, pH, humidity, insects, pests, rodents, fungi, mold, mycotoxins, and odor. Infested grain with insects and fungi cannot be used, resulting in significant losses, even if treated with chemical pesticides, which may cause undesirable odor and require additional cleaning and treatment before use. Addressing these issues on a continuous basis is crucial for successful long-term grain storage.

Ozone is the best alternative for grain & feed disinfection.

Ozone treatment has been used in various agro-food applications to mitigate the dangers of grain contamination. Several research studies have shown the efficacy of Ozone for grain & feed disinfection for the storage and preservation of food grains, wheat grains, and wheat flour, as well as a microbial disinfectant agent for microflora, bacterial, fungal, and mould contamination. E.g. Ozone kills every storage insect, with a remarkably low cost of operation.

Despite its effectiveness as a disinfectant, ozone gas does not leave a chemical residue on food or food contact surfaces because it decomposes quickly into nontoxic products. Also, ozone gas is generated on-demand, on-site, and does not require transportation or storage, unlike traditional chemical sanitizers. The use of ozone reduces the company’s environmental impact and costs without altering grain quality.

Ozone is a highly reactive gas. When ozone gas is generated and used in concentrated form, it has the ability to kill bacteria, viruses, and other pathogens, making it a powerful tool for grain disinfection.

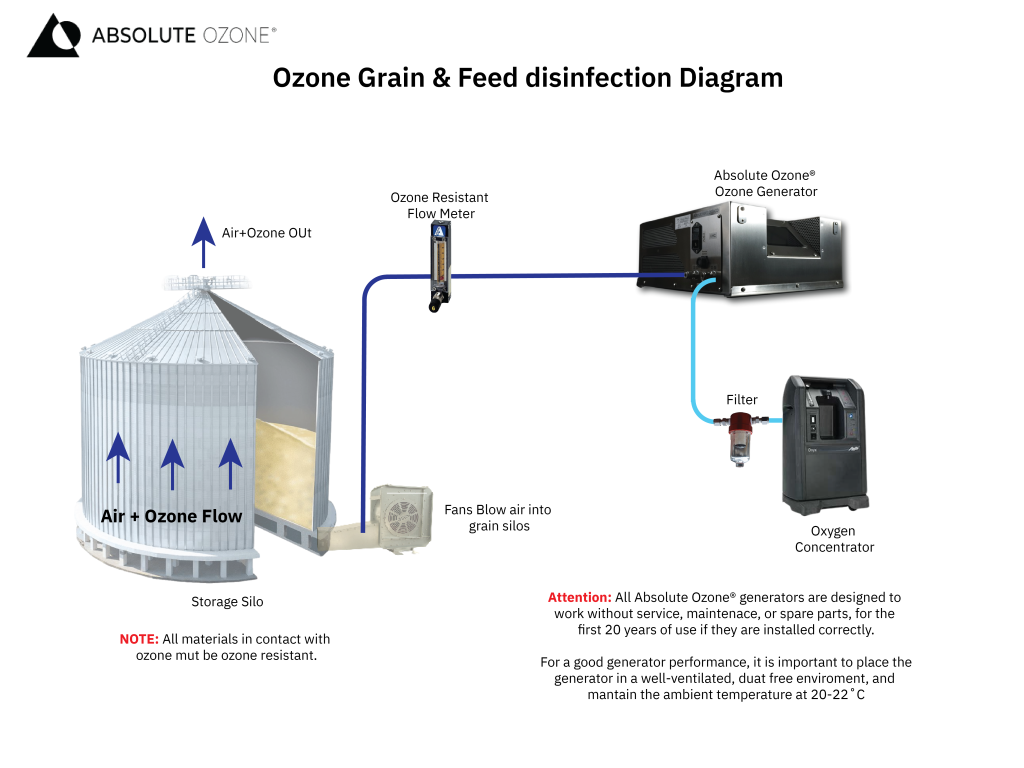

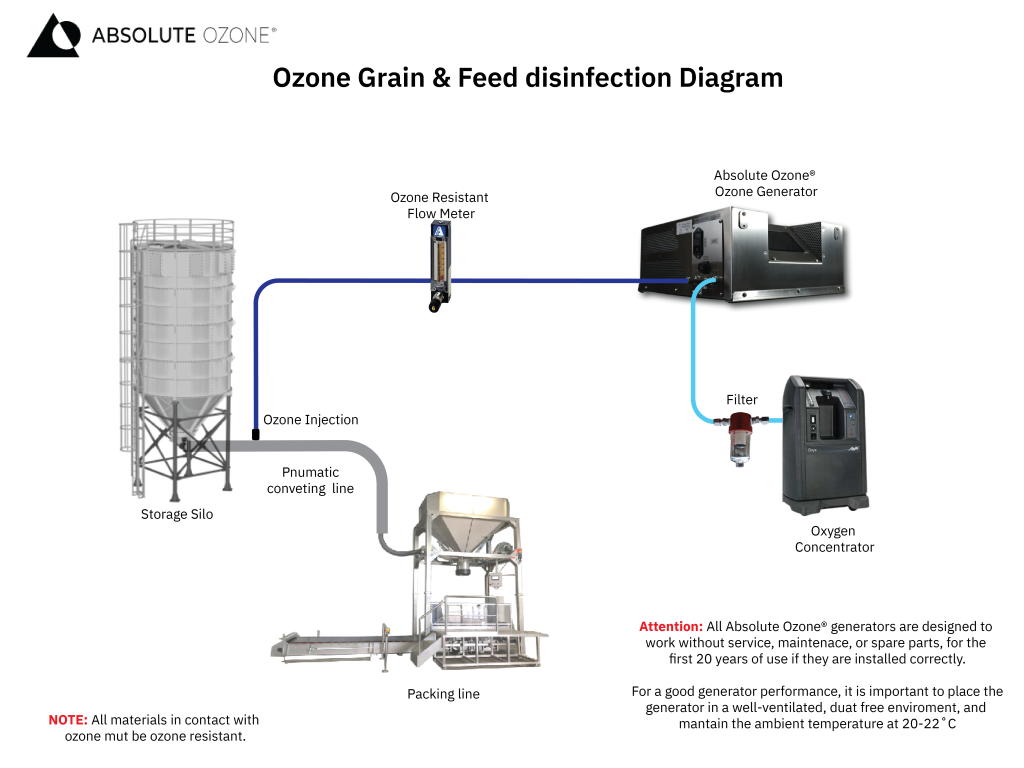

Ozone generators work by converting oxygen molecules (O2) into ozone (O3). This is achieved by passing an electric current through the oxygen molecules, breaking the bonds and creating ozone. The ozone gas is then mixed with air or water and introduced into grain storage, transportation pipelines, or containers, where it actively seeks out and destroys any pathogens present.

One of the advantages of using ozone for grain disinfection is that it is a safe and eco-friendly alternative to other chemical disinfectants. Ozone breaks down into oxygen (O2) within a few minutes after use, leaving no toxic residue or harmful by-products. It is also highly effective, as ozone has a strong oxidizing effect that can kill even the most resistant of pathogens.

A key component of grain treatment, particularly when it comes to avoiding mold growth, is the concentration of ozone gas. Ozone treatments have been shown to be a successful way of preventing mold formation and maintaining grain quality. For example, the ozone concentration typically ranges from 0.05 to 0.1 ppm (parts per million) for rice grains. This concentration ensures that the ozone is able to penetrate the grain kernels and effectively eliminate mold growth. It is important to note that using a higher ozone concentration can result in over-oxidation and harm the quality of the rice grains.

Advantages of Ozone Fumigation of Grain Storage

- Ozone gas is produced on site

- Ozone is a powerful oxidant, and it kills all insects in the grain

- Ozone kills bacteria and other undesirable microorganisms in the grain

- Ozone deprives rodents like rats of oxygen and prevents them from entering grain storage.

- Ozone prevents the growth of molds and mycotoxins in the grain

- Ozone is approved as a sanitizer for contact with food and food equipment because its effective against many microbes

- Ozone eliminates odor in the stored grain.

- Ozone does not modify the organoleptic and nutritional value of the grain.

- Ozone automatically decays into diatomic oxygen and escapes into the atmosphere.

- Ozone does not leave behind any residue, odor, or chemicals, and is environmentally safe.

- Ozone is compatible with organic food processing.

WHY ABSOLUTE OZONE?

Different industries have been using Absolute Ozone® technologies worldwide for the past 25 years. Further, We ensured the correct concentration and application time to reduce levels of bacterial and fungal contamination. Our Absolute Ozone® systems have been delivering excellent results being an economical and effective alternative to traditional methods.

Absolute Ozone® engineers will be happy to provide you with unlimited technical assistance in your project to ensure its success.

Contact us now to access more information about ozone implementation in your project and initiate the further exploration of possibilities for your project.