Ozone Library

Sizing of Ozone Equipment

Sizing an ozone generator can be made simple with the right information. However, obtaining said information can sometimes be problematic.

“When selecting and sizing an ozone generator for your application, there are three important points to consider for effective results”

When selecting and sizing an ozone generator for your application, there are three important points to consider for effective results:

- Ozone demand (g/m3, mg/l, ppm, etc.): The most important information when selecting an ozone generator for your project or application is an ozone demand, or how much ozone per volume of water or air you need to apply to remedy an existing problem, which is typically the inactivation of harmful or dangerous bacteria or contaminants. You can determine ozone demand through various means, including:

- Published Scientific Studies

- CT (Concentration Time) Factor Tables for Bacteria Deactivation

- Experience or Pilot Testing

- Government Regulations

- Volume: Water, air, gas, etc., which you need to treat (m3/h, GPM, SLPM, etc.)

- Compensation: Implementing proper compensation is crucial to account for factors limiting ozone participation in the reaction. This compensation considers the efficiency of the ozone dissolution process, ozone concentration, and ozone decay half-life.

Once you know the ozone demand, you multiply it by the volume of gas, water, etc., that you need to treat. This will give you the theoretical amount of ozone required for your project in an ideal situation.

Implementing proper compensation for all contributing factors that limit ozone participation in the reaction factors about ozone production will allow you not to undersize the ozone system and achieve greater treatment results.

“To help you better understand how you can do the calculations, let us review the following practical example for swimming pool ozone application”

To help you better understand how you can do the calculations, let us review the following practical example for swimming pool ozone application.

- Ozone demand:

To prevent any bacteria, algae or viruses from growing in the pool and to keep water safe and crystal clear, especially with organic dust and pollen entering the water in outdoor applications, you need to have a theoretical residual ozone concentration of 0.07 ppm, as we have learned from our experience over many years. An indoor pool will most likely work well with 0.05 ppm of residual ozone as indoors, you do not have organic dust, pollen, etc., blown into a pool by wind, dramatically increasing bio load and ozone demand. Some government recommendations suggest 0.03 – 0.05 residual ozone concentration, but I would never go as low as 0.03. CT factor for most bacteria diction is about 0.02 ppm/min - Calculation:

For a 50 m3 example swimming pool, To create 0.07 ppm ozone concentration (outdoor pool) in ice-cold water, you need to dissolve 0.07 g/m3(ppm) x 50 m3 = 3.5 g of ozone. - Compensation:

In reality, these calculations have to be compensated this way to find the actual size of the generator required:

At 25˚C, the half-life of ozone in water is ~15 minutes (0.25 hours).

To compensate for natural ozone decay in the water

you will need to dissolve 3.5 g ÷ 0.25 = 14.0 g/h and not 3.5 g/h as calculations without compensation may suggest.

Ozone Pool Calculator

“A mistake most people who designed the ozone system make”

And now about a mistake most people who designed the ozone system make:

For some reason, it is common to think that you can dissolve 100% of the ozone that any ozone generator produces, which is impossible and incorrect.

In our test, we have seen the following dependency:

Ozone Concentration vs Amount of Ozone Dissolved From Total Produced

| Ozone Concentration | Amount of Ozone Dissolved From Total Produced |

|---|---|

| 1% wt | ~10% Maximum for dry air fed air-cooled ozone generators |

| 3% wt | ~20 – 30% Over 90% of all ozone generator manufacturers work in this range, including Pacific Ozone, Del Ozone, Clear Water, etc. |

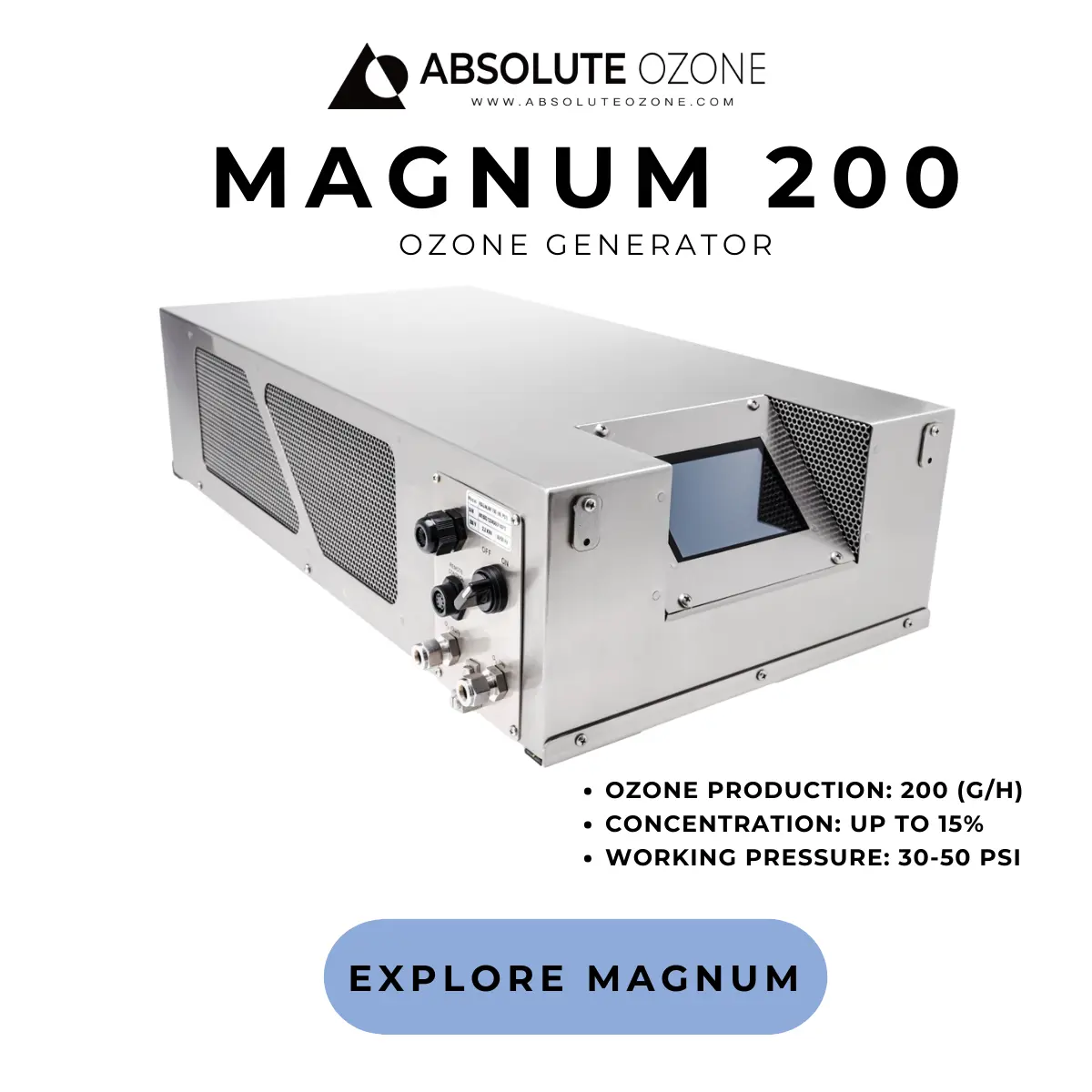

| 5-7% wt | ~50 – 70% Absolute Ozone® typical Nano, Atlas, Magnum generator performance, and just a few other generators |

| 8-10% wt | ~80 – 90% Absolute Ozone® Atlas 30 performance, plus most good quality water-cooled generators |

| 10-14% wt | ~95% Atlas 30 at low flows and the best quality large-size water-cooled generators |

| 14-22% wt | ~97% OAtlas 30 at low gas flows and just a few water-cooled ozone generators. |

We used cold water and a correctly tuned Venturi injector. If bubble diffusers are used, the dissolve efficiency will drop about 7-10 times.

For example, if you need to dissolve 14 g/h of ozone, your generator can dissolve only 50% at 5%wt: you need to select an ozone generator producing 14 g/h ÷ 0.5 = 28 g/h or 30 g/h, as it is more common on the market. Absolute Ozone® Atlas 30 can dissolve about 27 g/h from 30 g/h produced. It can accommodate a larger or the same size swimming pool with heavier bathers load or warmer temperature.

Summary: If the above information is not clear enough for you and you still have some questions, please contact us at office@absoluteozone.com, and we will gladly assist you free of charge.